It didn’t take long for Josef Prusa to follow up his popular CORE One 3D printer with a beast of a machine: the CORE One L. This “large” printer with a 300 x 300 x 330 mm build volume is a major shift from Prusa Research’s well-known i3 style. It still shares many of the same parts as the CORE One and MK4s, which will keep production costs down, but the CORE One L has a new AC-powered aluminum heat bed for even coverage and replaces a substantial amount of steel with lighter aluminum. This allows the CORE One L to have twice the print volume of the original machine while only taking up 10% more space.

It's unlikely the CORE One L will have a kit version, as the AC-powered heat bed is not for tinkerers. The 3D printer is still built with easy maintenance in mind and open source parts for lifetime repairability. The printer is also designed to operate completely offline if you choose, without dependence on the cloud for complete security. However, if you enjoy the convenience of mobile apps, the Prusa App offers remote printer operation, full access to Printables.com for model selection, and a lite version of PrusaSlicer for custom slicing on the go.

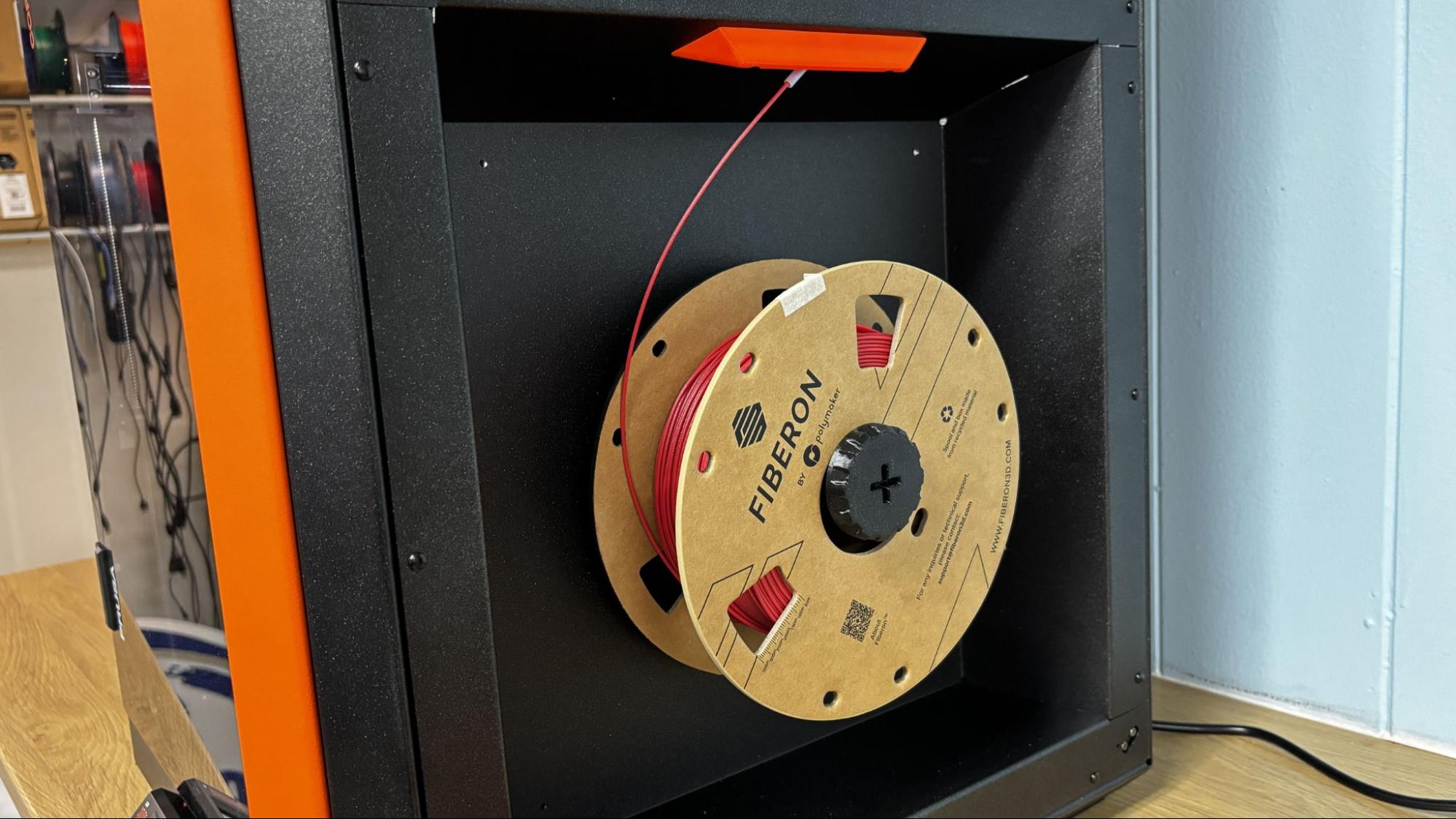

The CORE One L has a few clever tricks up its sleeve: it can flip the top vent open or close on its own, a flip of a switch makes loading (and running) TPU super easy, and strategically mounted fans control air flow and heat so the door can remain closed at all times. The chamber can hit 60 °C, making engineering-grade filaments as easy to run as PLA. It will also be the first 3D printer compatible with Prusa-backed OpenPrintTag, an open source initiative to create a universal “smart” spool with NFC tags that customers can reuse as they wish.

The CORE One L retails at $1,799 (including import duties and tariffs) and comes with 24/7 customer service and a complete ecosystem. This machine lives up to its reputation and is one of the best 3D printers we’ve tested to date.

Specifications: Prusa CORE One L

Swipe to scroll horizontally

Build Volume | 300 x 300 x 330 mm (11.8 x 11.8 x 12.99 in) |

Material | PLA/PETG/TPU/ABS/ASA /PC (up to 290 degrees) |

Extruder Type | Direct drive |

Nozzle | .4mm (Highflow CHT & Hardened Steel) |

Build Platform | PEI spring steel flex plate |

Bed Leveling | Fully automatic |

Filament Runout Sensor | Yes |

Connectivity | USB, LAN, Wi-Fi, App |

Interface | 3.5″ color screen touch screen with additional knob |

Machine Footprint | 469×521×635 mm (18.5×20.5×25in) |

Machine Weight | 21.9 KG (48.28 lbs) |

MSRP | |

Release Date | November 19, 2025 |

Prusa CORE One L: Included in the Box

The Prusa CORE One L comes 98% assembled. It includes a full set of tools and a full 1 kg spool of Galaxy Black Prusament PLA (plus a bag of Gummy Bears). There’s also a USB stick with models to test out and a handbook on 3D printing with your new machine. The PrusaSlicer is available for free download from the website.

Design of the Prusa CORE One L

The CORE One L is at its heart a larger CORE One, with a few critical changes. The most obvious is the size, now sporting a 300 x 300 x 330 build volume, which is about twice the size by volume, if not exactly plate size.

The slim, all-steel exoskeleton now has aluminum walls to cut down on heft, which means the new printer checks in at about the same weight (48 pounds) as the smaller CORE. This keeps it still somewhat manageable to move by a single person and sit on a desk.

It has the same indents on either side to conceal the spool holder and customizable storage space, though now magnets will only stick to the frame. The door and upper parts of the side panels are translucent black polymer. The top panel snaps into place. The top vent can now be opened or closed by the printer itself. It’s still not exactly airtight, with many gaps at the seams, but a few gaps in the frame won’t spoil the system.

The exoskeleton provides a strong, stiff frame for the printer while also minimizing materials and avoiding the cheap plasticky feel we get from other brands. The indented sides reduce the interior space of the printer, making for less space to heat.

The biggest change to the CORE One L is the heat bed, which is now a solid chunk of aluminum, heated with AC power. It provides uniform heating from corner to corner, which is essential with such a large surface. There are two fans underneath the bed to distribute the heat like a convection oven. This eliminates the need for a second heating system, as the bed can now be used more efficiently to warm the entire chamber for technical filaments.

The CORE One L still shares many 3D parts with its Prusa siblings, which are produced at the large Prusa Research print farm in Prague (or in Delaware by Printed Solid if you buy one in America). CORE One 3D parts are made with PC Blend Carbon Fiber, printed on a combo of MK4s and CORE One machines. Prusa also does its own injection molding, which you can see on the LCD case.

Another thoughtful touch is the door hinge, which can be flipped if you rather have it open on the other side. The door can completely open 180 degrees, but Prusa encourages users to go ahead and keep it closed for any material, thanks to their active cooling system. The door has a sensor that will warn you to keep it shut and stop the print when the door is opened. This is a nice safety feature for schools, parents of small children, and pet owners. Thankfully, the sensor can be switched off if you want the freedom to poke your nose or a camera in there.

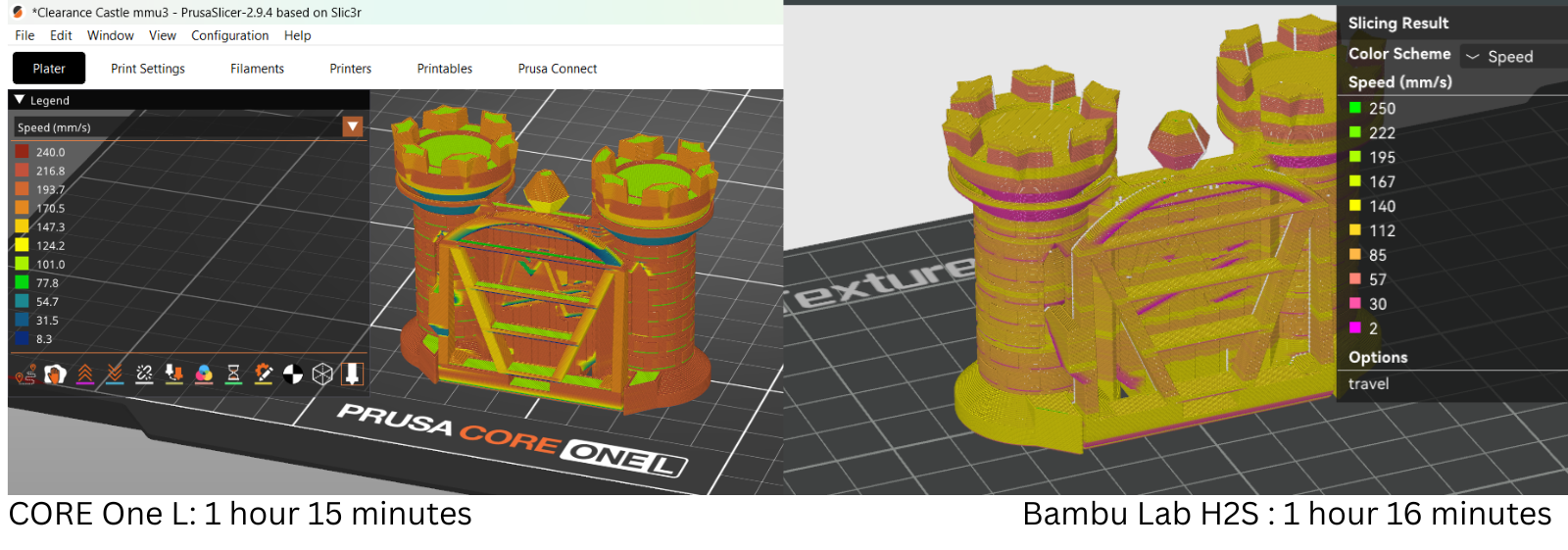

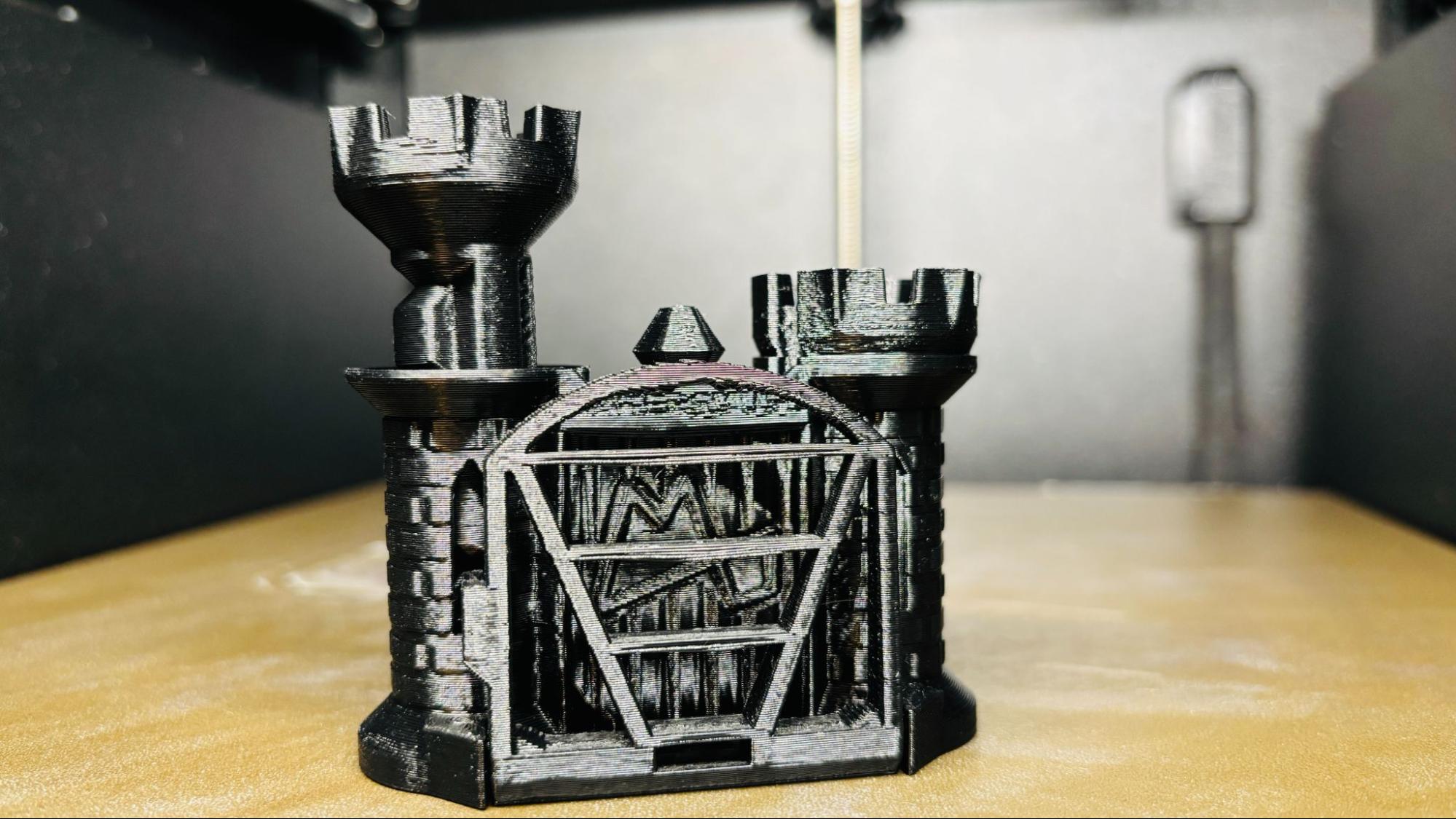

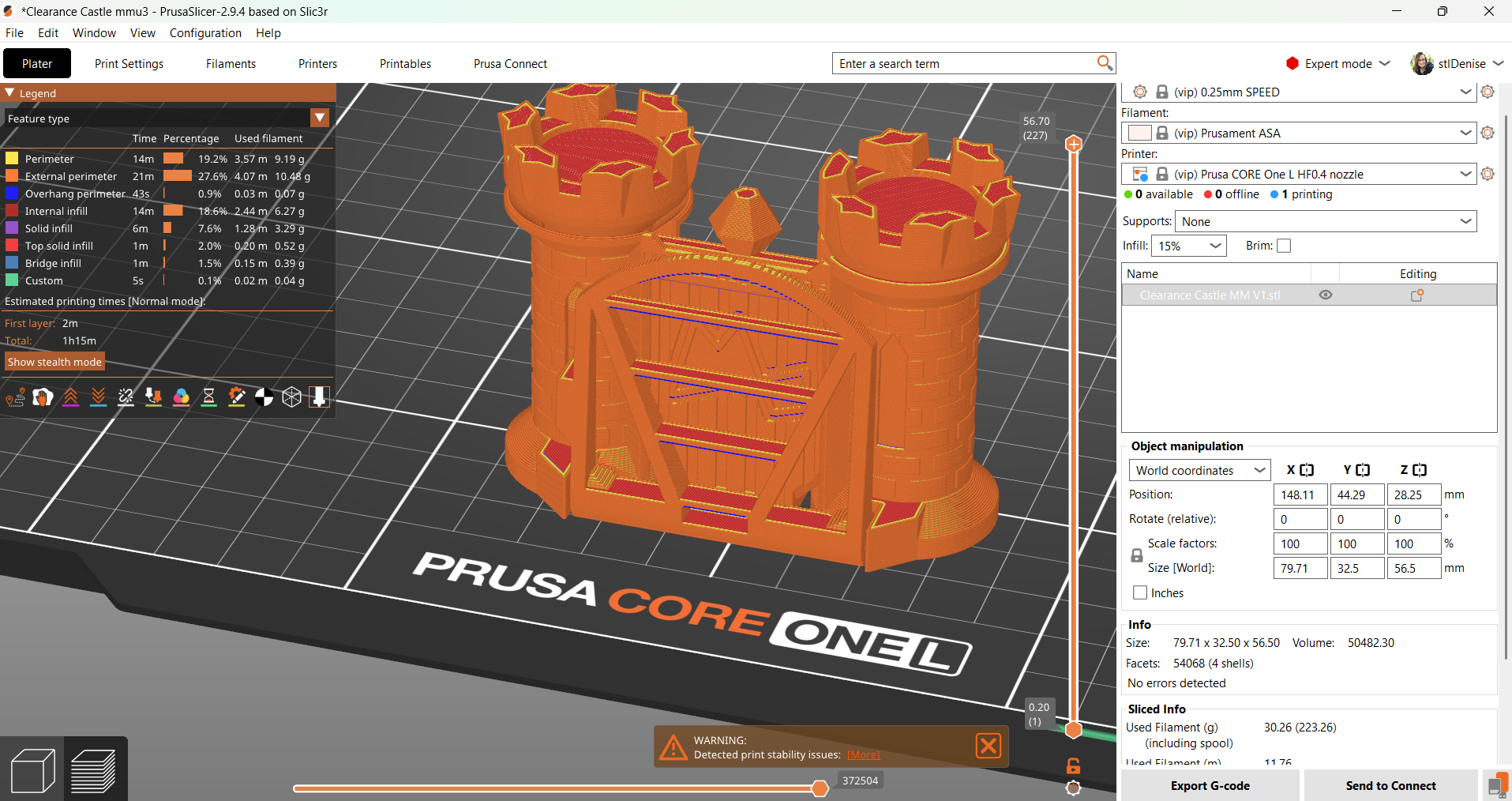

The CORE One L specs don’t include acceleration rates, as the company is famous for putting quality over speed. The machine does come with a high flow nozzle, input shaping and factory tuned print profiles for over 200 filaments. Still, I opened up PrusaSlicer to see what kind of settings they’re using for speed and acceleration. The top printing acceleration rate of 3000 mm/s² would not impress a Bambu user who easily has twice the speed. However, acceleration isn’t everything. Using their default settings, both the CORE One L and the similarly sized Bambu Lab H2S printed a Maker’s Muse calibration castle in about one hour and 15 minutes using .25mm layer height and default settings. Sure, the Bambu might be faster printing a big, plain box, but how often do you print things that are so boring?

The CORE One L finally has an onboard accelerometer, though it’s completely factory calibrated and ready to print as soon as you plug it in. It also has an NFC antenna to make getting the machine online and connected to the Prusa app and slicer very easy. The app is entirely optional for those who wish to keep their printers offline. The CORE One L has a USB port for manually loading files, which is the printer’s only place for file storage.

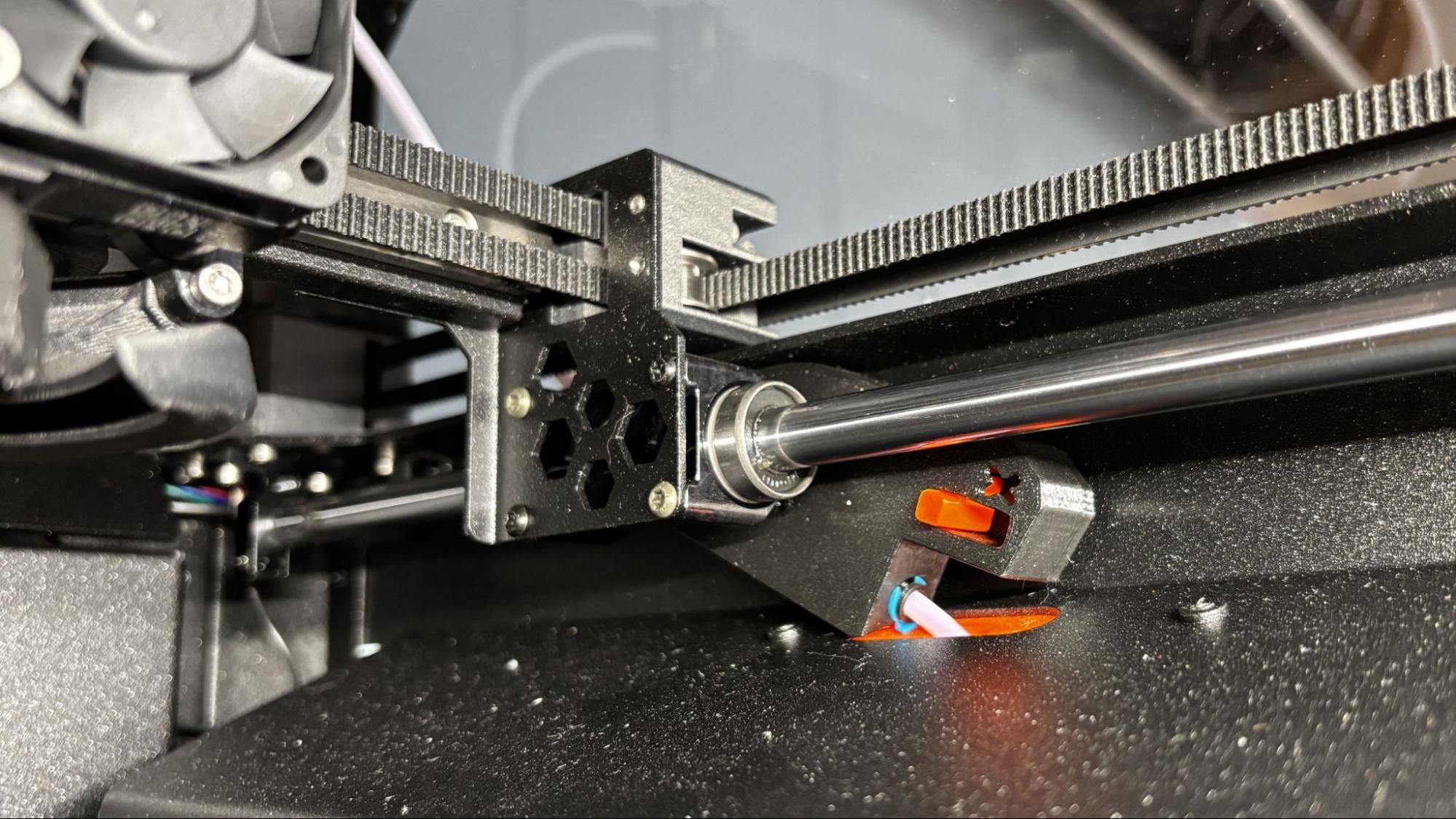

Like the CORE One, bed leveling is fully automatic, with no manual adjustments. First layers go down perfectly smooth thanks to a load cell sensor that has replaced the bedslinger’s PINDA probe. The sensor is connected to the nozzle, which allows the CORE One L to physically tap the print surface for a more precise measurement. The sensor is also used to calculate Z Height, and it does it so well that there is no need for human intervention. Of course, there’s still a live Z adjustment available in the menu should you need it. During testing, we did not.

Assembling the Prusa CORE One L

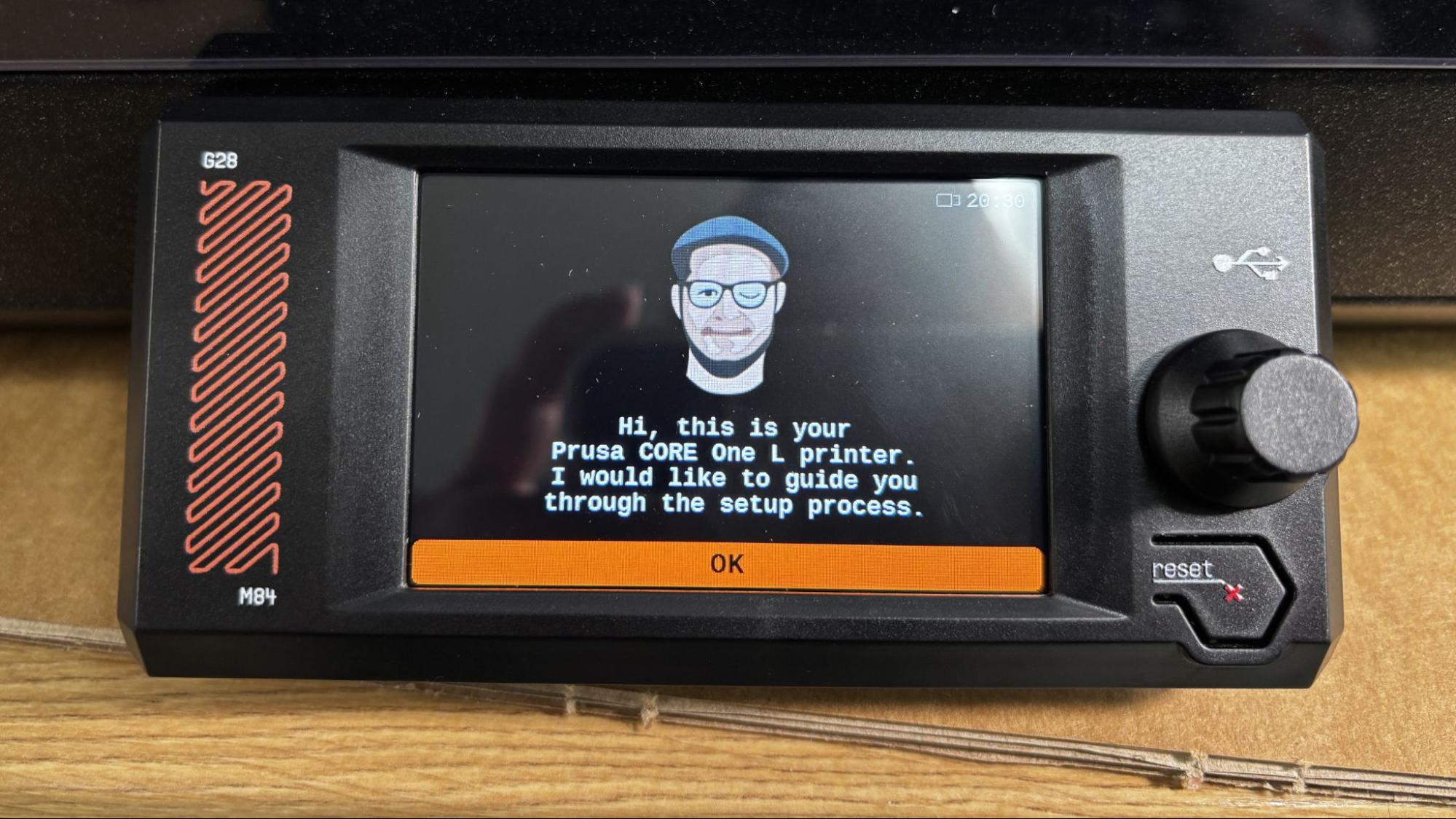

The Prusa CORE One L comes nearly assembled. You just have to unpack it and remove a few screws that held the bed down during shipping. The screen arrives packed inside, attached to the front trim plate, and just needs to be slapped on the printer with magnets.

Our machine came with the optional filtration system, which did need more complex assembly. That involves removing the back panel to access the electronics, plugging the fans to the board and screwing everything back together. It was fairly straight forward, but I did have to hunt down the directions online.

Leveling the Prusa CORE One L

Bed leveling is a no-brainer, as the Prusa CORE One L is fully automatic. There are no manual adjustments and no need to adjust the Z offset. The printer uses a load cell sensor connected to the nozzle, which physically taps the print surface for precise measurement.

The printer trams the bed and calculates the required z height before each print.

Loading Filament on the Prusa CORE One L

Loading filament is very simple. Simply place the spool into side mounted rack and feed the plastic into the reverse Bowden tube until it reaches the hotend. The printer will automatically detect it and pull it in the rest of the way. The screen will then ask what kind of material you’re using to set the temperature. Once it gets hot enough, it will pull the filament into the hotend and ask if the color has changed. If it has, you can say yes and move on. If the answer is no, it will purge more material.

To remove material, go to the Filament menu from the main screen and click unload. It will remember what material was last installed, determine if the filament is still there, and then heat it to the appropriate temperature. Once hot, it will retract the plastic until you can easily remove it.

If you’re running flexible filaments, there’s a switch where the tube enters the chamber that allows you to switch off one of the filament sensors (another is on the tool head). This allows soft TPU to load as easily as PLA and I didn’t have any trouble at all.

Preparing Files / Software for Prusa CORE One L

You’ll need to download PrusaSlicer, which is free and open source. It is developed by Prusa Research and serves as the foundation for many other slicers. It comes with hundreds of profiles for every material and nozzle size that Prusa Research makes.

PrusaSlicer can also directly access Printables.com, which offers a wide selection of free file models for both fun and practical prints. If you’re using the mobile app, files can be sent directly from Printables to the online EasyPrint slicer and then directly to your printer if you choose to have it online.

Printing on the Prusa CORE One L

The CORE One L comes with a full 1 KG roll of Prusament PLA Galaxy Black. If you want more colors and materials like silks and multicolor filaments, you should check out our guide to the best filaments for 3D printing for suggestions.

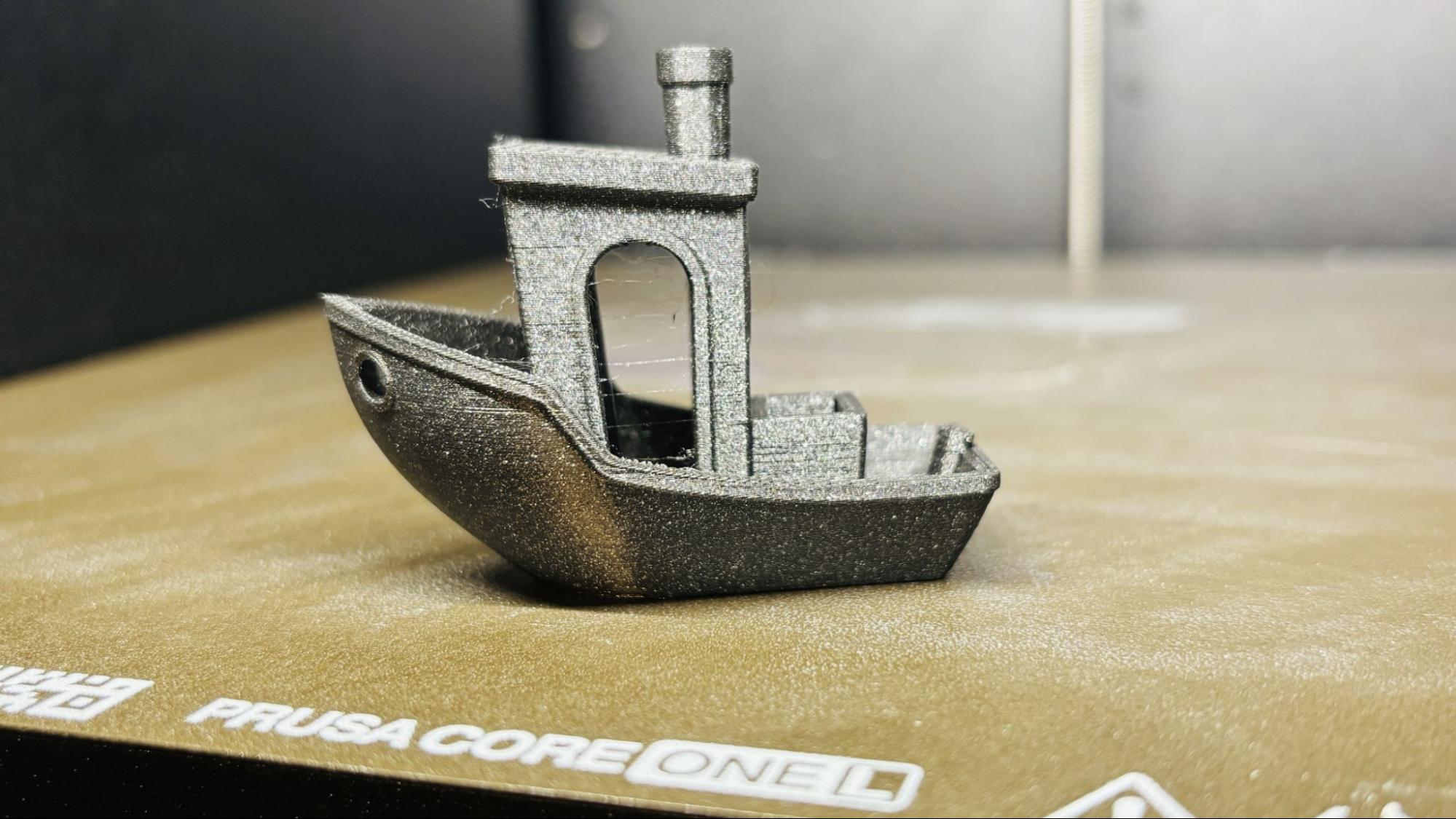

We used the sample material to print a Benchy to see what the CORE One can do with its fastest default slicer settings. We used Speed Benchy rules for fairness: 2 walls, 3 top and bottom layers, 10% infill, a .25 layer height and .5 layer width. Using these settings, we got a very nice benchy in 23 minutes with a bit of wisps probably due to the humidity in the house.

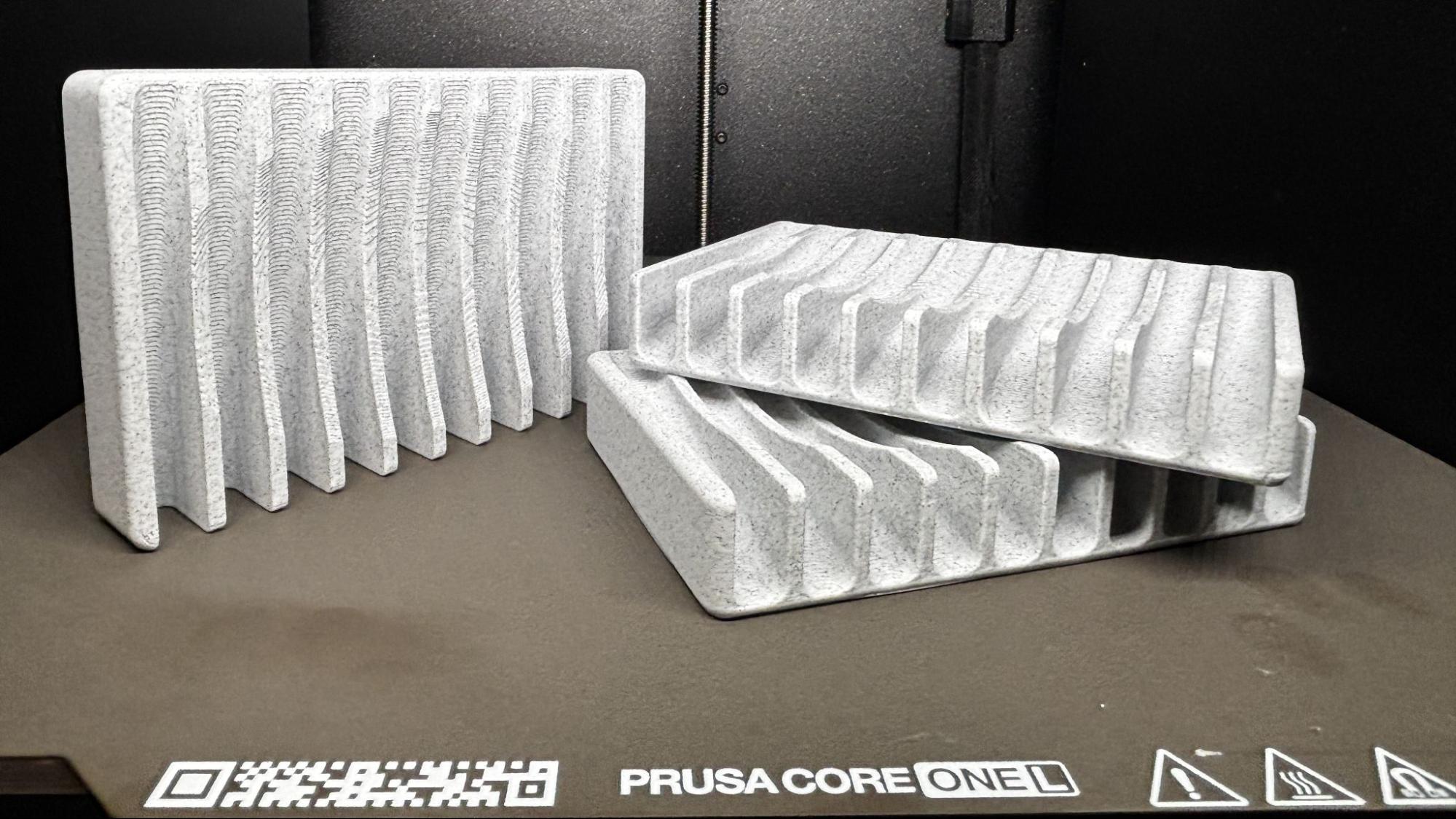

I printed a few soap dishes I found on Printables for a practical PLA print. These were a little chonky looking despite the .2 layer height, due to the curves. It had 3 walls for strength printed in Prusament PLA Marble Grey, which makes home goods look more posh. It took 5 hours and 54 minutes to print three of them.

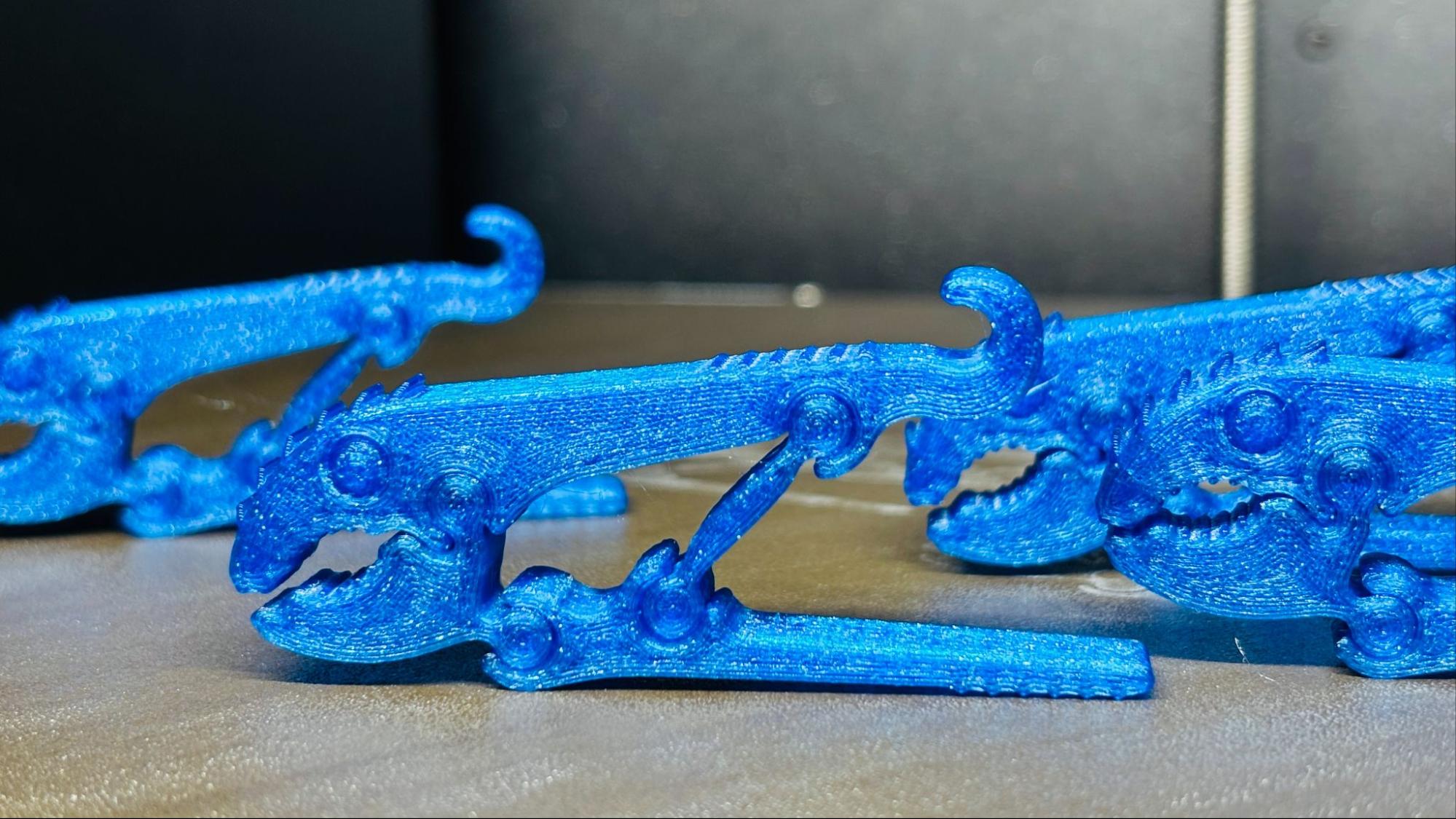

I also printed some cute clips, which mix practical with whimsical. These “Vicegriptor” locking clips have surprising bite when printed in PETG. A word of warning – you need to be very careful loosening them up the first time, or you risk breaking the print in place joints. Once they’re limbered up, they work really nice for holding chip bags and the like.

I printed eight at a time on the CORE One L’s roomy bed, taking 3 hours and 13 min, using a .2 layer height and default settings. This was printed in Greengate’s recycled Deepwater Blue, a sparkly filament created for 3D Print Bunny.

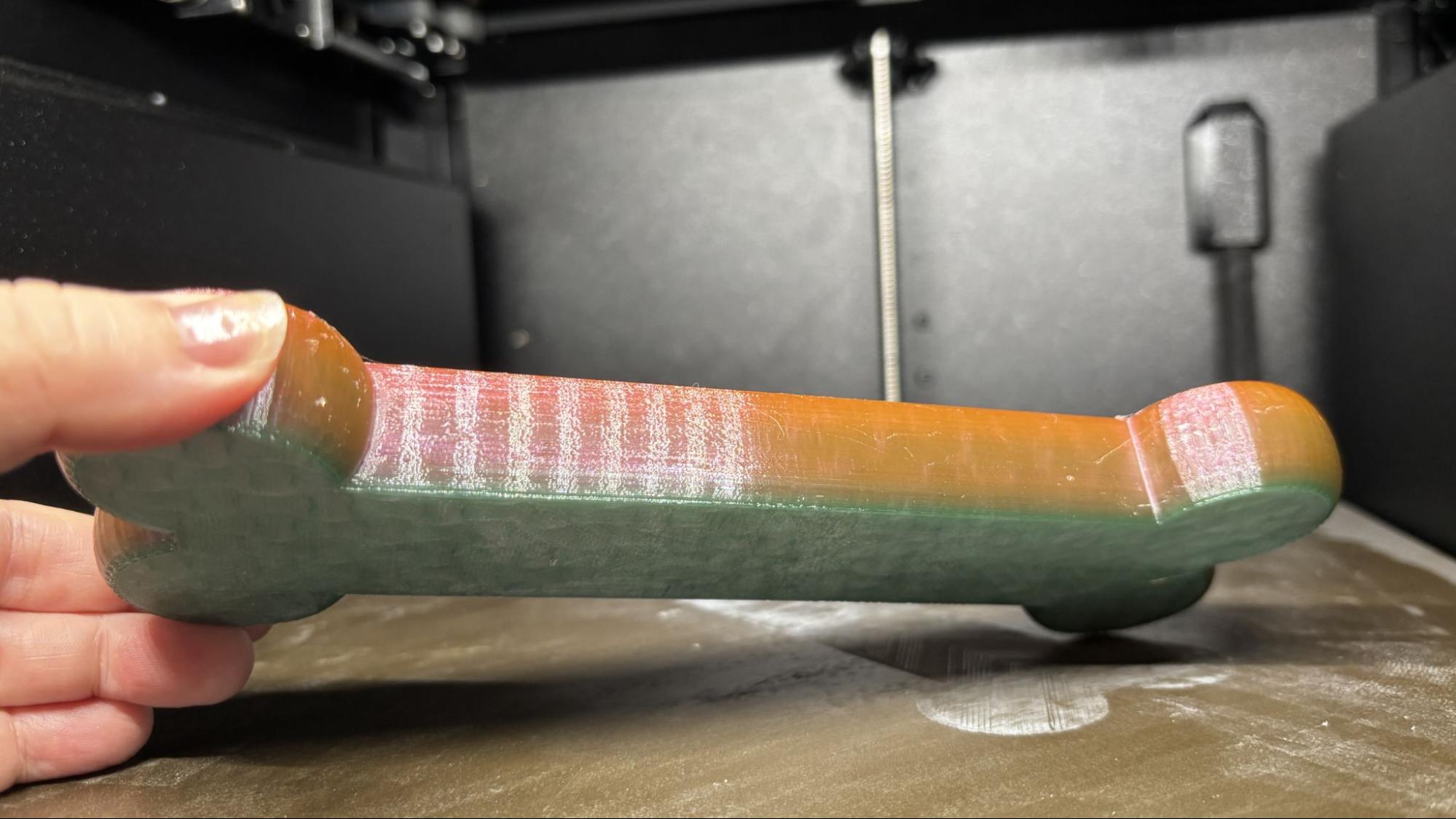

For TPU I made another ill-fated dog toy for my Standard Poodle Ripley. The print was excellent, but 3D printed dog toys for strong chewers is still not that great. The filament loaded very easily, thanks to the new switch, and I had no trouble at all pushing it through to the Nextruder.

This printed in 6 hours and 6 minutes, using Inland Rainbow TPU and a .2mm layer height. It lasted about 6 hours after I gave it to the dog too. Before the dog destroyed it, it had very nice smooth and glossy surfaces and very slight blemishes from layer lines.

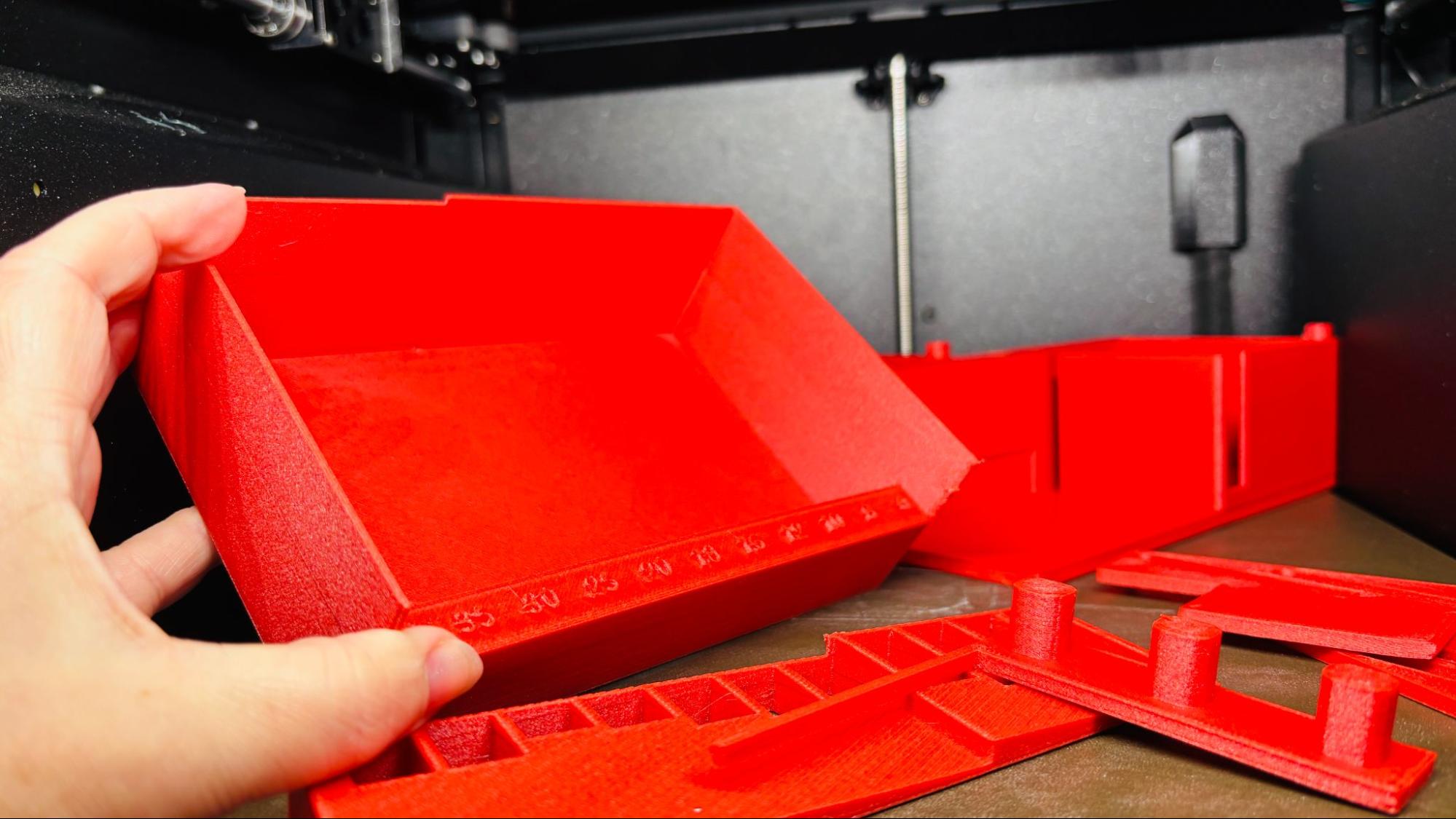

We ran a lot of high-temperature material from it, like this Fiberon Red PET-GF15 by Polymaker. This is a form of Polyethylene terephthalate, like PETG, but without the G (glycol), which is usually added to make the material behave. Instead, Polymaker added 15% glass fiber to make the PET stiff, dimensionally stable, and thermal resistant. It prints fast and super hot, and this needed 280 °C on the nozzle and 80 °C on the bed. I filled the bed with parts, and it printed very nicely without warping. There were some goobers on the edges that will brush off.

Bottom Line

The CORE One L is a great addition to the Prusa lineup, filling a space between the “medium” MK4/CORE One and the Prusa XL tool changer. It gives you Prusa quality and security in a larger size without having the larger pro price tag. It has a retail price of $1,799 (including import duties and tariffs) and comes with 24/7 customer service and a complete ecosystem.

Its new aluminum bed with even AC-powered heating is excellent, and it has a few perks like the camera, TPU switch, and self-opening top vent that could be easily added to the smaller CORE One. It will also be the first printer to try out OpenSourceTag when it hits the market.

We’re also keeping our fingers crossed for a tool changer mod through a partnership with Bondtech, but details are still vague as of this writing.

If a Prusa CORE One L seems just a bit too spendy for your budget, the smaller Prusa CORE One comes in at $999 for a kit. The delightfully budget-friendly Bambu Lab P1S Combo is currently on sale for $549, and if you need some massive CORE XY size, the Creality K2 Plus is worth checking out at $1199.

3 hours ago

10

3 hours ago

10

English (US) ·

English (US) ·