Serving tech enthusiasts for over 25 years.

TechSpot means tech analysis and advice you can trust.

What just happened? As the world's leading semiconductor manufacturer, TSMC's production halt following the 6.4-magnitude earthquake in Taiwan has triggered industry-wide concern. Its customers are closely monitoring the company's damage assessment and potential production disruption, which could impact global chip supply chains.

The powerful 6.4 magnitude earthquake that struck southern Taiwan on January 21 has led to a disruption in production at TSMC. While there were no reported fatalities, the tremor caused considerable damage throughout the region, prompting the firm to implement immediate safety measures. TSMC evacuated staff from its central and southern production sites and temporarily halted operations as a precautionary step.

Fortunately, initial inspections revealed that TSMC's facilities largely withstood the quake without major structural damage, thanks to their design, which accommodates seismic events of up to magnitude 7.

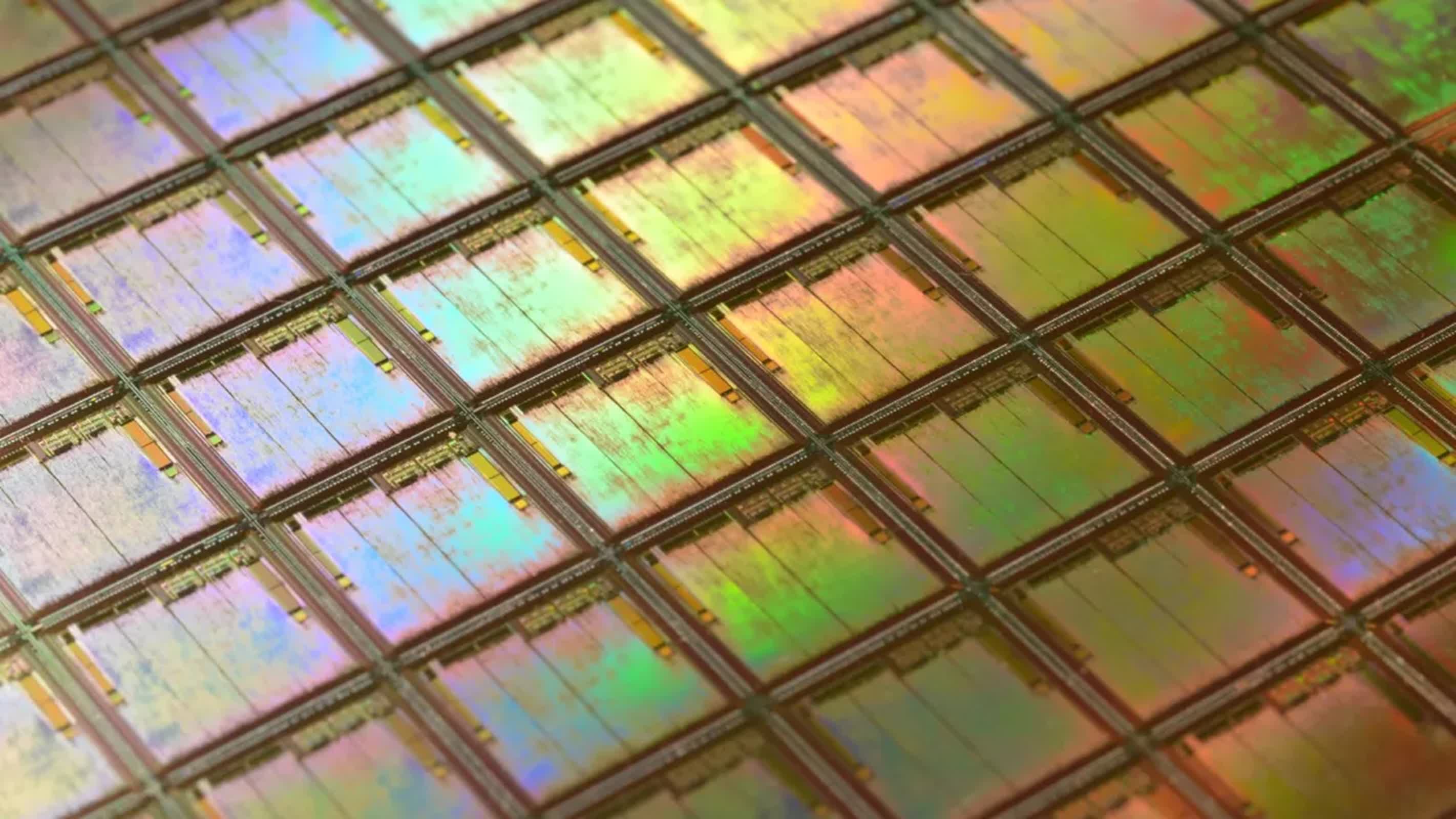

Despite this resilience, the earthquake may have affected between 10,000 to 20,000 wafers currently in production. These wafers are critical for TSMC's operations, particularly within its advanced fabrication plants located in the Southern Taiwan Science Park, including Fab 14 and Fab 18. These facilities are responsible for producing state-of-the-art chips utilizing N3 technology for major clients such as Apple and Intel.

Although inspections confirmed no damage to essential infrastructure or utilities like electricity and water, the sensitive technical equipment within these fabs may require recalibration due to vibrations from the earthquake and its aftershocks.

TSMC is expected to update its recovery timeline in the coming days.

The financial implications of this event appear manageable for TSMC. In the last quarter alone, the company processed over 3.4 million wafers, averaging around 37,000 wafers per day.

Consequently, even though 20,000 wafers may seem significant, they represent only a small fraction of TSMC's overall output.

TSMC is expected to resume full operations relatively quickly.

Historical context provides further reassurance; a similar earthquake in April 2024 resulted in losses estimated at $92 million but did not severely disrupt long-term operations or output. In fact, overall tool recovery in TSMC's fabs reached more than 70 percent within 10 hours of that earthquake.

Other semiconductor manufacturers in Taiwan are also assessing their operations after implementing precautionary shutdowns, including UMC and Innolux.

Meanwhile, Taiwanese media report that TSMC suppliers have mobilized to get production running as soon as possible. This mobilization is part of TSMC's long-standing enterprise risk management system, which is designed to minimize potential disruptions.

English (US) ·

English (US) ·