Serving tech enthusiasts for over 25 years.

TechSpot means tech analysis and advice you can trust.

In context: 3D printing is slowly becoming mainstream, having moved beyond functional prototyping, rapid tooling, trinkets, and toys. We have already seen people use 3D printers to create fashion products, high-performance automotive parts, and even robotic prosthetics for humans and animals. Researchers have now used the technology to build a fully functioning optical microscope for just $60.

Researchers at the University of Strathclyde in Glasgow, Scotland, built the microscope using OpenFlexure's open-source design, which is freely available online.

The team used a Raspberry Pi to control the system, adding an off-the-shelf camera and a light source to craft what they claim is the world's first completely 3D-printed functional microscope for histological imaging.

With all the components, the microscope weighs around 3 kg, or 6.6 lbs. According to New Scientist, the device took only 3 hours to build from the ground up, at a cost of just £50 (around $60).

The researchers programmed a Mars 3 Pro 3D printer to build the cheap plastic lenses using a photopolymerizing clear resin. They were designed to meet the exact specifications of the Edmund Optics 12.7 mm diameter plano-convex lens with a 35 mm focal length, and cost a fraction of the expensive glass lenses traditionally used in powerful microscopes.

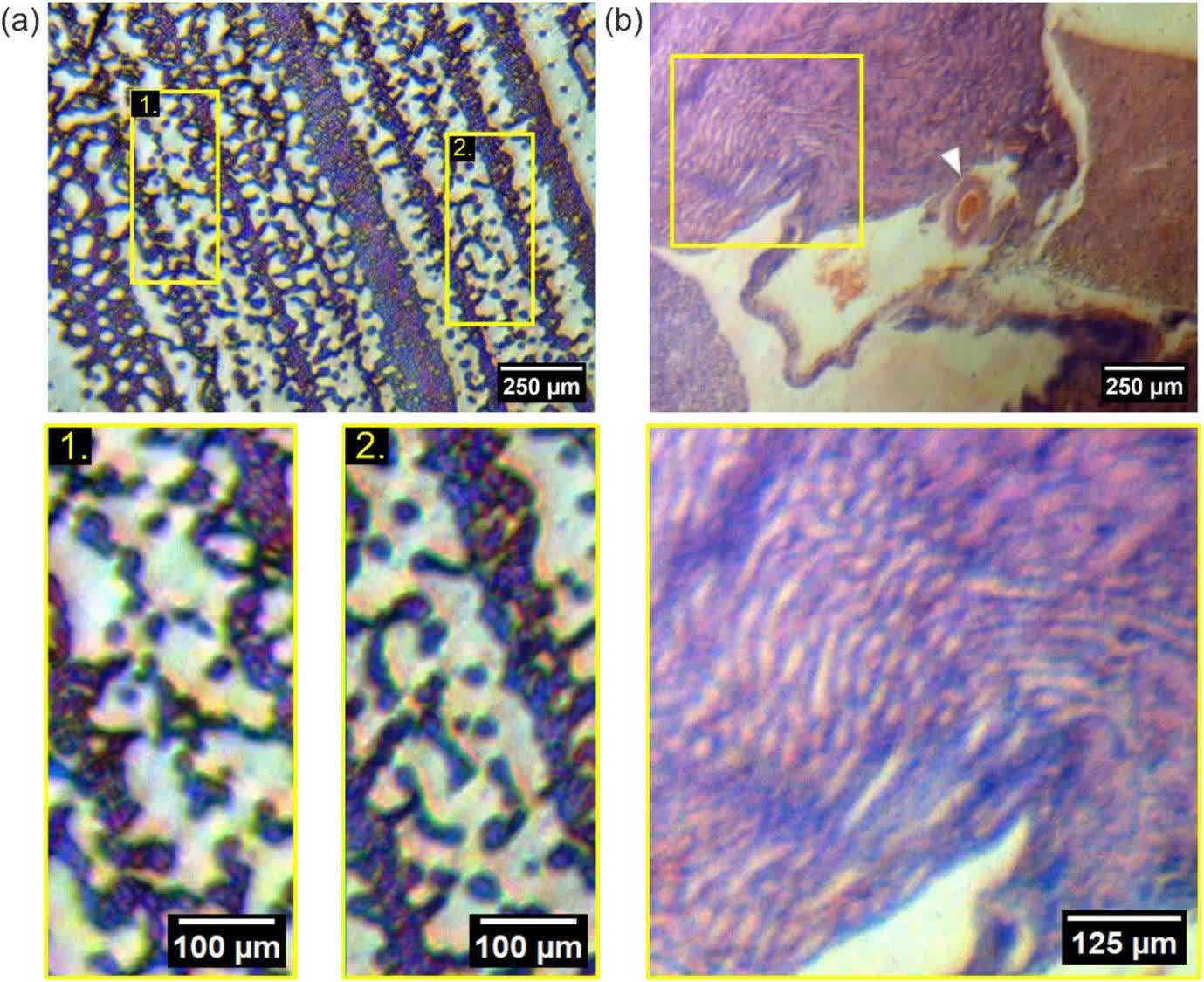

The team tested the 3D-printed microscope with a blood smear and a tissue sample from a mouse kidney. The magnified image had a field view of 1.7 mm with a single cell spatial resolution of around 5 micrometers. It clearly depicted critical sub-cellular anatomical details, such as renal tubules. This is a major step up from earlier DIY Raspberry Pi microscopes, which couldn't see sub-cellular details with the same degree of clarity.

Over the years, researchers and DIY hobbyists have assembled microscopes using OpenFlexture's open-source blueprints in over 50 countries around the world, including laboratories in Antarctica. However, these devices need custom glass lenses costing hundreds of dollars, making them too expensive for many use cases.

The University of Strathclyde team developed a workaround that drastically cut the total cost of the device, potentially democratizing microscopes for researchers on a shoestring budget. The researchers believe that their revolutionary design will pave the way for more advanced models with higher-powered lenses offering alternative apertures and magnifications.

Image: 1. Dr Liam M. Rooney/University of Strathclyde (via New Scientist) // 2. Biology

/cdn.vox-cdn.com/uploads/chorus_asset/file/24083307/DSC03735_processed.jpg)

English (US) ·

English (US) ·