Researchers from Boston University, UC Berkeley, and Northwestern University have created something that sounds straight out of a sci-fi movie: a “quantum light factory” squeezed onto a 1 mm² silicon chip. Built using a standard 45 nm CMOS manufacturing process—the same kind used for standard x86 and ARM processors—this breakthrough brings quantum hardware a step closer to the world of mass production. The work, published in Nature Electronic, could pave the way for scalable quantum computing that doesn't require exotic setups, instead relying on mass production techniques that we already employ today.

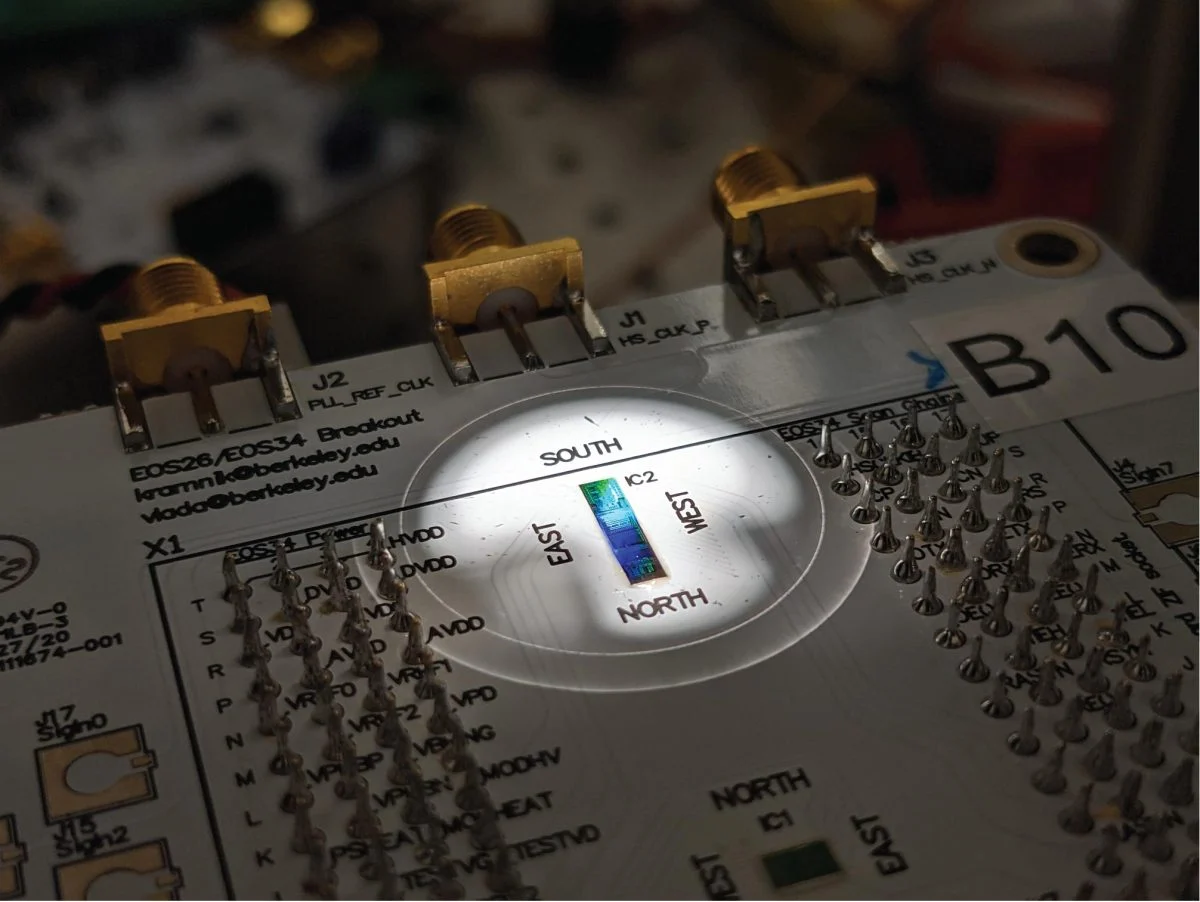

Think of this chip as a prototype for a future quantum factory line. It packs 12 tiny silicon loops, called "microring resonators," each acting as a generator of photon pairs with special quantum properties. These photon pairs are the lifeblood of many quantum technologies, but producing them usually requires fragile lab setups. Here, they’re generated directly on a chip no bigger than a fingernail.

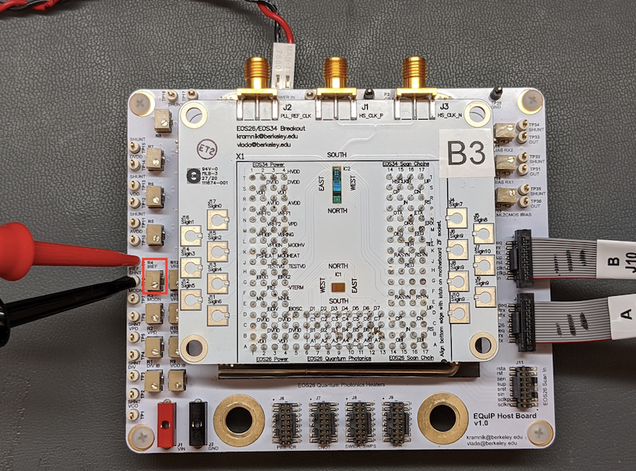

What makes this remarkable is that the chip doesn't just produce quantum light; it’s more about keeping that light stable. Microring resonators are powerful but temperamental—small temperature changes or manufacturing quirks can throw them out of tune, halting the photon flow. To solve this, the researchers built a feedback system directly into the chip; each resonator has a tiny photodiode to monitor its performance, along with miniature heaters and control circuits that adjust it on the fly. This self-tuning approach means all 12 resonators can work together in perfect sync, without the bulky stabilization equipment usually needed.

“This is a small step, but an important one,” said Miloš Popović, associate professor at Boston University and one of the senior authors. “It shows we can build repeatable, controllable quantum systems in commercial semiconductor foundries.” That’s the real story here—this isn’t just a niche, bleeding-edge lab demo, but proof that quantum chips can be made with the same industrial techniques used to build CPUs and GPUs. Of course, quantum computing is nowhere near the maturity of standard semiconductors powering our devices today, but this is a step closer to that eventuality.

Let's talk about the most important revelation. The team’s choice of CMOS (Complementary Metal-Oxide-Semiconductor) is a game-changer. CMOS is the backbone of modern electronics, used by companies like TSMC to mass-produce everything from smartphones to supercomputers. While the 45 nm node used here isn’t cutting-edge, it’s proven, cost-effective, and compatible with the vast infrastructure of silicon manufacturing. The chip was built using a platform co-developed with GlobalFoundries and Ayar Labs, a company already leading the charge in optical interconnects for AI and high-performance computing.

This overlap with the AI world is no coincidence. Nvidia CEO Jensen Huang recently called out microring resonators—like those on this chip—as key components for scaling AI hardware via optical connections. This new research shows that the same photonics technology could also unlock scalable quantum systems. It’s not hard to imagine a future where quantum and AI hardware share similar silicon platforms. Moreover, Nvidia is already heavily investing in this field, so we can only expect development to ramp up.

The term “quantum light factory” isn’t just for flair, either. Just as classical chips rely on streams of electrons and optical networks depend on laser light, future quantum technologies will need a steady supply of quantum light. By proving that these quantum light sources can be built, stabilized, and replicated on silicon, the team has shown that quantum hardware can move beyond one-off experiments and into something that can be scaled like traditional computing.

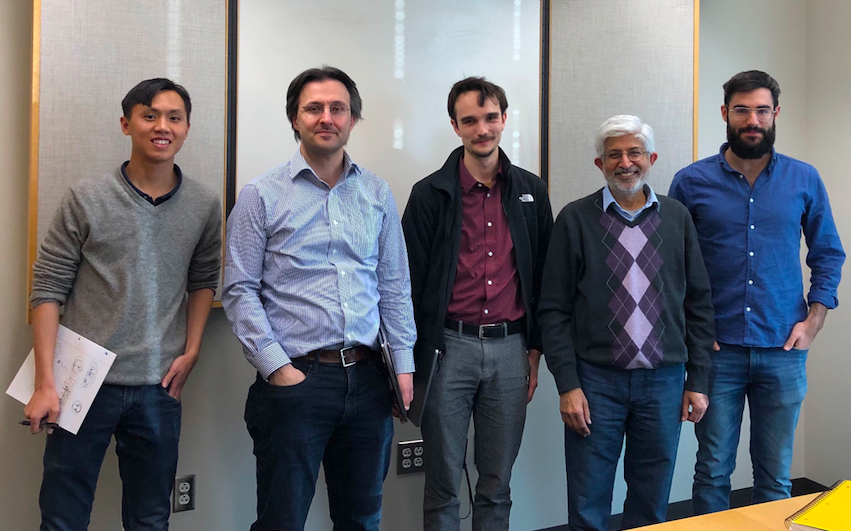

Some of the researchers involved are already taking this expertise into industry roles. Team members have joined companies like PsiQuantum, Ayar Labs, and Google X, all of which are betting heavily on photonic and quantum technologies. It’s another sign that this field is moving rapidly from academic research to real-world products, even if they're sometimes more fun-oriented than revolutionary.

Backed by the National Science Foundation’s Future of Semiconductors (FuSe) program, the Packard Fellowship, and the Catalyst Foundation, the project shows how far interdisciplinary collaboration can go. Photonics, electronics, and quantum optics are worlds apart, but this chip proves they can be brought together on a commercial platform.

If Intel’s 4004 microprocessor marked the start of mass-produced computing power, this 1 mm² quantum light factory could be remembered as the first step toward mass-produced quantum hardware. What once needed an entire lab bench now fits onto a silicon wafer—and that’s a leap worth paying attention to. Who knows? Maybe a decade from now, you'll be seeing a new TSMC competing for quantum computing excellence, especially now that there's already an operating system for it out there.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

4 months ago

57

4 months ago

57

English (US) ·

English (US) ·