In the quest for more powerful electronic chips, a persistent challenge has been how to efficiently dissipate the increased heat they generate.

Among the promising solutions, researchers are now looking towards bionics - drawing inspiration from nature - for innovative technologies that could eventually revolutionize AI data centers.

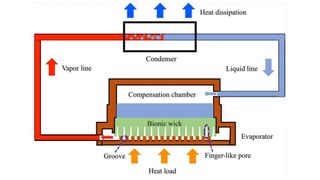

A research team led by Prof. Ye Hong from the University of Science and Technology of China has developed a groundbreaking bionic ceramic wick for Loop Heat Pipes (LHPs), inspired by the natural transpiration process of leaf stomata. Their research, published in Langmuir, addresses a key limitation of traditional LHPs, which use wicks with uniform pore sizes, reducing efficiency at high heat fluxes due to vapor blockages and increased thermal resistance.

Promising early results

The newly developed bionic wick features an asymmetric pore structure, which optimizes heat transfer by overcoming these challenges, offering a more effective solution for high-power chip cooling.

The design mimics leaf stomata, with straight finger-like pores serving as vapor channels, significantly reducing vapor transport resistance, and enhancing heat dissipation. This structure enables a higher critical heat flux, allowing for better management of high-power chip cooling. The use of ceramics, instead of metal, for these wicks also offers enhanced corrosion resistance and thermal stability, critical for the long-term performance of advanced electronics.

The manufacturing process employs phase-inversion tape casting, commonly used for producing porous ceramic membranes. This innovative method not only allows for creating the desired multiscale pore structures in a single step but also ensures a solid and consistent output.

Initial tests of the bionic wick within LHP systems have shown promising results. By optimizing the balance between capillary force and flow resistance, the bionic wick efficiently transports working fluids and enhances the system's thermal performance. This advancement has the potential to extend beyond just computing hardware, with applications in aerospace, microelectronics, and energy sectors.

This pioneering approach could redefine thermal management strategies in data centers powering artificial intelligence, paving the way for more efficient and sustainable solutions inspired by the natural world. Researchers are hopeful that continued development and adaptation of these bionic structures will help overcome existing challenges and meet the demands of next-generation electronics.

:quality(85):upscale()/2024/10/29/625/n/1922564/ec222ac66720ea653c5af3.84880814_.jpg)

:quality(85):upscale()/2024/10/25/846/n/49351082/bfc0fdb3671bef086c3703.42134063_.jpg)

:quality(85):upscale()/2021/07/06/971/n/1922153/7d765d9b60e4d6de38e888.19462749_.png)

:quality(85):upscale()/2024/10/29/957/n/1922441/c62aba6367215ab0493352.74567072_.jpg)

:quality(85):upscale()/2024/10/29/987/n/49351082/3e0e51c1672164bfe300c1.01385001_.jpg)

English (US) ·

English (US) ·