Netanel Raviv and a team at the McKelvey School of Engineering (part of Washington University in St. Louis) are continuing to develop a way to embed traceable digital 'fingerprints' into 3D-printed objects.

Initially reported by

3D Printing Industry, the markers are designed in a way to be detectable, even if the printed object has been broken, because they can be identified with just a fragment of the object. Depending on the fingerprint, information such as what printer was used and when the object was created can be embedded in the print.

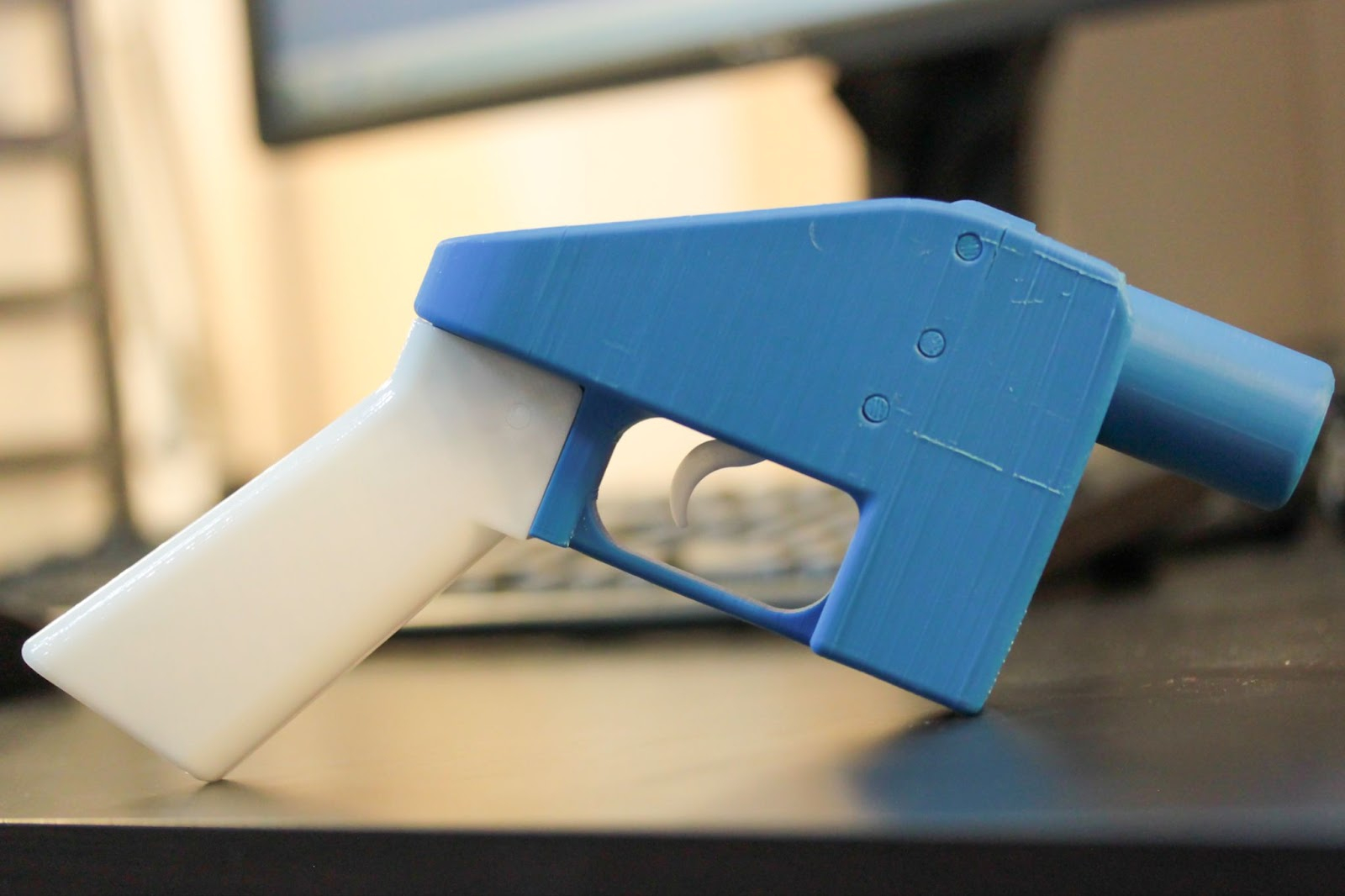

One of the biggest practical use cases for this development is, of course, forensics. Traceable fingerprints are crucial for helping law enforcement track ghost gun manufacturing operations. We reported on a similar approach just a few months ago in which police were able to identify markers left behind when printing.

The process, created by the team at Washington University, is known as Secure Information Embedding and Extraction (or SIDE for short). The fingerprinting process adds a permanent marker to the object, which can be deciphered later to determine any data factors that were put in during the printing process, such as the owner of the printer that was used.

Details on exactly how this is done are scarce, with Raviv saying it's accomplished through "mathematical contributions and new security mechanisms." Perhaps the point is to keep potential bad actors from attempting to subvert the technology. But given that these are plastic objects, it's also unclear how traceable a print might be if someone just takes a minute or two to melt the print after using it.

This development is an extension of Raviv's previous work, which was presented in 2024 at the IEEE International Symposium. Last year, the focus was mainly on the ability to recover information from broken 3D-printed parts. Now it seems the effort is in placing intentional markers into the 3D printing process so they can be more easily interpreted in the future.

At the moment, it's nearly impossible to determine much about the machine used to print an object by studying the object alone. That doesn't mean we won't see more efforts to change that as time goes on. After all, 2D printer makers have embedded model-identifying dots in printers since the 1980s (though it wasn't disclosed until much later).

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button!

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

2 months ago

29

2 months ago

29

English (US) ·

English (US) ·