Serving tech enthusiasts for over 25 years.

TechSpot means tech analysis and advice you can trust.

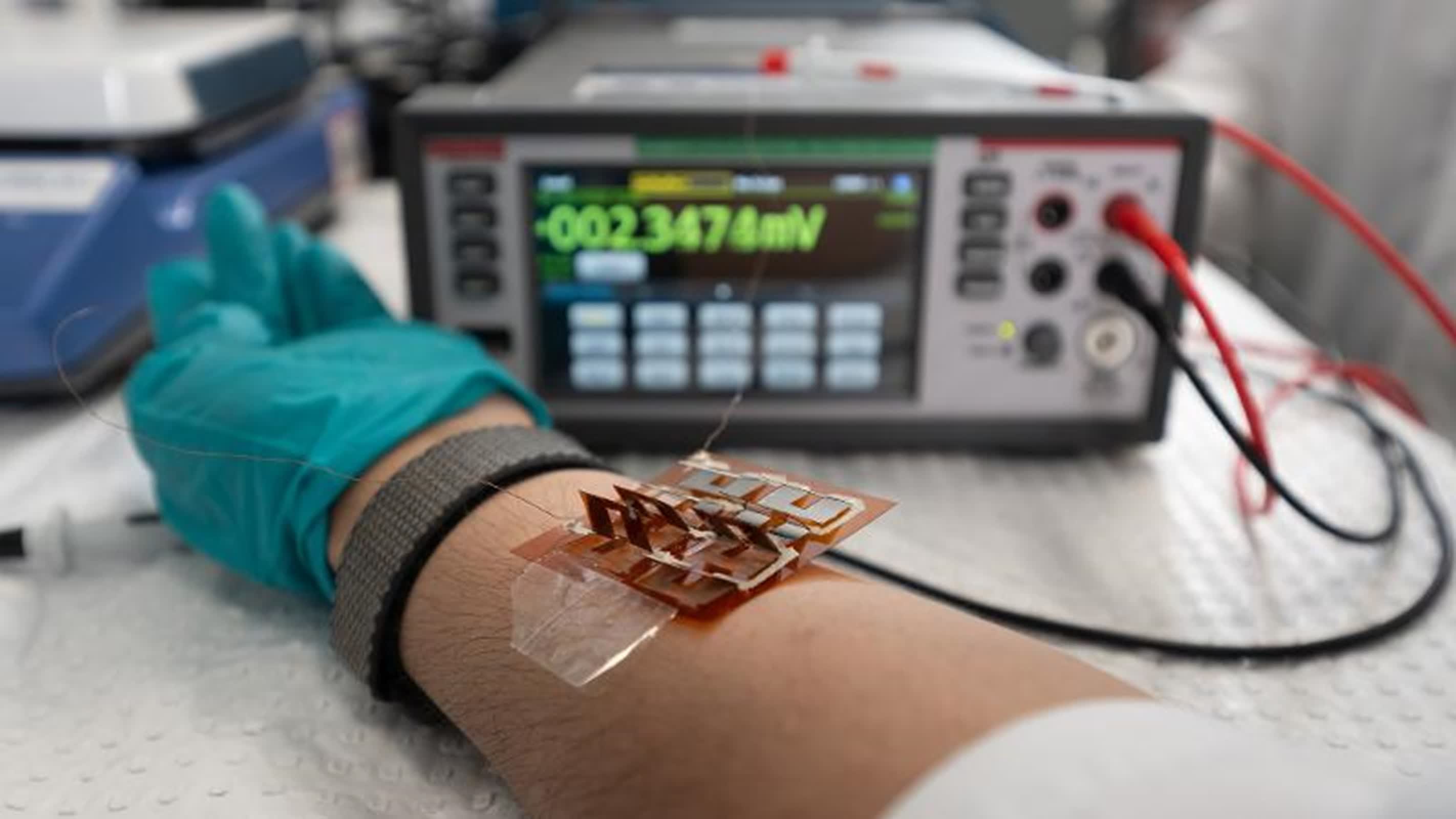

Forward-looking: A new development in flexible thermoelectric film technology could pave the way for a new generation of wearable devices and cooling solutions. Researchers at Queensland University of Technology (QUT) have created a flexible film that addresses the longstanding challenges of flexibility, manufacturability, and performance.

Australian researchers have engineered an ultra-thin, flexible film capable of harnessing body heat to power wearable devices, potentially eliminating the need for batteries. This technology, which could also cool electronic chips in smartphones and computers, marks a significant advancement in a field that has been steadily progressing for years. The breakthrough builds upon foundational work by research teams worldwide focusing on energy harvesting and thermal management.

Thermoelectric devices that can convert temperature differences into electricity have long been sought after for wearable electronics. However, creating flexible, efficient, and commercially viable versions has proven to be difficult. Limited flexibility, complex manufacturing processes, high costs, and insufficient performance have been among the roadblocks in scaling up and commercializing flexible inorganic thermoelectrics for wearable electronics and high-end cooling applications.

Professor Zhi-Gang Chen and his team at QUT appear to have addressed these challenges. Their research, published in the journal Science, introduces a cost-effective technology for producing flexible thermoelectric films. The key innovation lies in the use of tiny crystals, or "nanobinders," that form a consistent layer of bismuth telluride sheets, enhancing both efficiency and flexibility.

The team's method integrates solvothermal synthesis, screen-printing, and sintering techniques. Solvothermal synthesis creates nanocrystals in a solvent under high temperature and pressure, while screen-printing enables large-scale film production. The sintering process heats the films to near-melting point, effectively bonding the particles together.

The resulting printable film consists of Bi₂Te₃-based nanoplates as highly oriented grains and Te nanorods as nanobinders. When assembled into a flexible thermoelectric device, the film's power density ranked among the highest for screen-printed devices.

The QUT team's approach is not limited to bismuth telluride-based thermoelectrics. Wenyi Chen, the study's first author, noted that their technique could also work with other systems, such as silver selenide-based thermoelectrics, which are potentially cheaper and more sustainable.

This technology opens up a range of potential applications. "Flexible thermoelectric devices can be worn comfortably on the skin where they effectively turn the temperature difference between the human body and surrounding air into electricity," Professor Chen said.

Beyond powering wearable electronics, the film could be used for personal thermal management. For example, the integration of flexible thermoelectric devices into textiles opens up new possibilities for smart clothing with these devices used to create self-powered heated garments for cold environments.

Earlier research has shown that flexible thermoelectric devices can offer innovative solutions for energy harvesting and thermal management across various sectors.

In the automotive industry, flexible thermoelectric devices could be incorporated into vehicles to power battery-free distance detection sensors for autonomous driving by utilizing the temperature difference between a car's interior and exterior. These devices could also harvest energy from exhaust pipes and other heat-generating components, improving fuel efficiency and reducing emissions.

The medical field could also benefit greatly from this technology. Flexible thermoelectric devices could power implantable medical devices using body heat, eliminating the need for battery replacements and reducing the risk of complications. Additionally, they could enable continuous, non-invasive body temperature monitoring systems, providing valuable data for health monitoring.

On a larger scale, flexible thermoelectric devices have the potential to harvest waste heat from infrastructure. By conforming to the curved surfaces of pipes, machinery, or building components, these devices could generate electricity from previously untapped heat sources, contributing to more energy-efficient buildings and industrial processes.

English (US) ·

English (US) ·