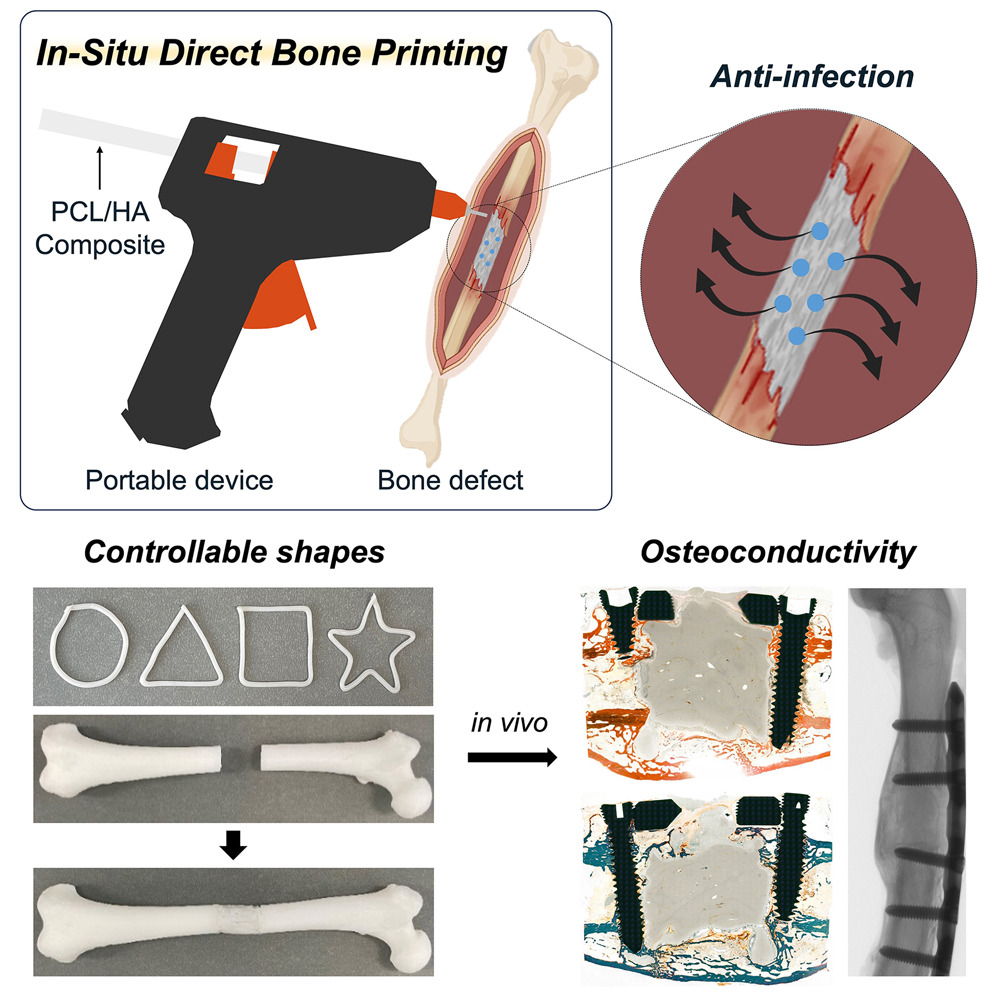

A research team at Sungkyunkwan University (SKKU) has developed a new bone graft technique that utilizes a modified glue gun and sticks composed of a bone mineral and biodegradable composite. When melted down, this material serves as a scaffold to encourage bone growth and performs better than traditional bone cement. Aside from that, New Atlas reports that it’s designed to make it easier and cheaper for surgeons to create customized implants in the operating room, reducing reliance on bone grafts or metal reconstruction.

“Our proposed technology offers a distinct approach by developing an in-situ printing system that enables a real-time fabrication and application of a scaffold directly at the surgical site,” said Biomedical Engineering Associate Professor Jung Seung Lee. He also added, “Because the device is compact and manually operated, the surgeon can adjust the printing direction, angle, and depth during the procedure in real time.”

The modified glue gun uses low-temperature printing, avoiding damage to surrounding tissues in the operating field. On the other hand, the ‘hot glue sticks’ are composed of a compound of polycaprolactone (PCL), a polymer used to stabilize the damaged bone, and hydroxyapatite, a naturally occurring material found in bone. Aside from these two materials, the researchers said that they could include antibiotics like vancomycin and gentamycin into the mixture, reducing the need for patients to take oral antibiotics and cutting the chance of developing antibiotic resistance while fighting infection.

This technique is designed to replace the commercial bone cement currently used in most orthopedic operating rooms. When compared to the traditional method over 12 weeks, the bone glue gun exhibited better performance, producing stronger bone tissue with a more natural structure. There were also no signs of inflammation or tissue damage around the area of application.

“The scaffold was designed not only to integrate biologically with the surrounding bone tissue but also to gradually degrade over time and be replaced by newly formed bone,” Lee said. “The results showed that the printing group exhibited superior outcomes in key structural parameters such as bone surface area, cortical thickness, and polar moment of inertia, suggesting more effective bone healing and integration.”

Although this orthopedic technique holds promise, it will still take a while before we see it in the hands of orthopedic surgeons and as part of the standard kit in an operating room. The team still needs to develop sterilization protocols and conduct pre-clinical studies as part of regulatory approval. They also must standardize the manufacturing of the device to ensure consistency. But once they’ve gone through all these roadblocks, it could potentially make bone repair faster and easier for both the medical team and the patient.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button!

2 months ago

32

2 months ago

32

English (US) ·

English (US) ·