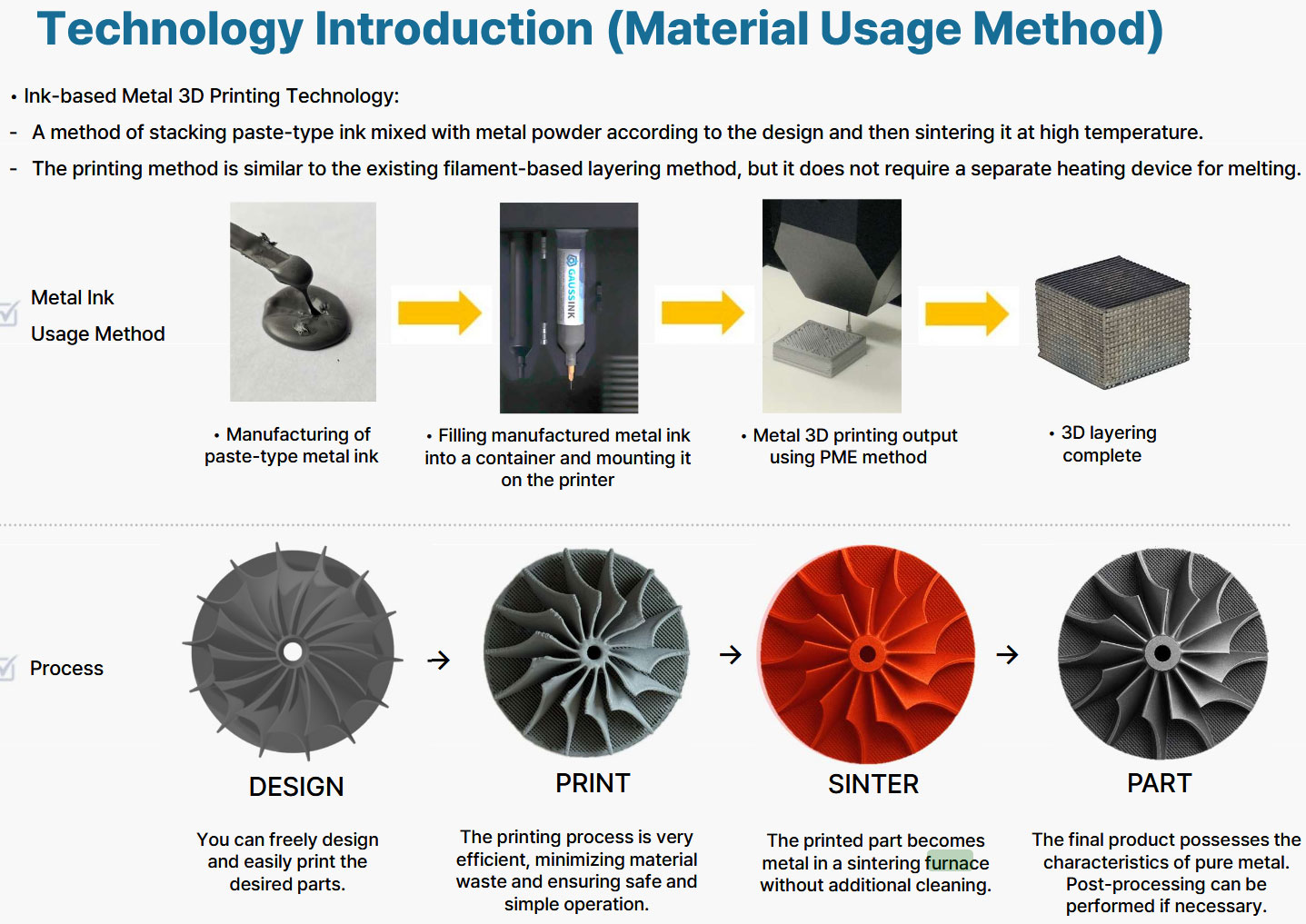

MetalPrinting was at CES 2026 with its next-generation metal paste 3D printer dubbed the Gauss MT90. This device sets itself apart in the metal 3D printing niche with its compact desktop form, by working at room temperature, and by leveraging office‑safe paste based (patent applied for) metal extrusion (PME) tech, which eschews powders. MetalPrinting claims the Gauss MT90 is “a game-changer that is reshaping the landscape of the metal 3D printing industry.”

Metal 3D printing has until now been the reserve of companies that are set up to work with large, expensive, and potentially hazardous machines. They typically use high temperatures and metallic dust materials – which heighten fire and explosion risks.

With the Gauss MT90, using PME tech, the size and hazards involved in metal 3D printing are greatly reduced. As you can see in the images, MetalPrinting’s new 3D printer looks a lot like many other desktop 3D printing devices on the market, and it even has user-friendly ‘printer cartridges.’ Its operating noise, of at about 40dB, is also reasonable.

The site shows that MetalPrinting has prepared ‘GaussInk’ cartridges with stainless steel, copper, titanium, nickel, iron, and even tungsten materials, and says “custom and alloy ink materials are available upon request.” These cartridges contain the PME paste-like inks.

In brief, the Gauss MT90 extrudes its inks at room temperature. An integrated HEPA filter minimizes any potential emissions into the surrounding space during this process. You can watch through the window, control and monitor it via a 7-inch touch display, and an AI-supported camera is on guard to make sure everything proceeds as it should.

To be clear, the Gauss MT90 output doesn’t simply dry and harden and give you usable output straight off the bed. The 3D printed part has to also be heated in a sintering oven, to strongly fuse the metal paste particles, before it is ready. There isn’t much information available regarding the sintering oven process, apparatus, or specifications.

We have previously covered metal 3D printing in space. That Airbus system, deployed in the ISS, was a relatively hazardous device to use in such a constrained environment, with its stainless steel filament melted at 2,192°F (1,200°C) to additively manufacture parts. At least it didn’t introduce powdered metal into the ISS’s cabin atmosphere…

The MetalPrinting Gauss MT90 3D printer won a CES 2026 Innovation Award. For availability and pricing details, you are encouraged to contact the company directly.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our latest news, analysis, & reviews in your feeds.

5 hours ago

7

5 hours ago

7

English (US) ·

English (US) ·