3D printing technology is evolving at breakneck speed, and features considered cushy add-ons five years ago are now becoming everyday essentials. 3D printer forums used to buzz with questions about necessary mods just to make their machines usable, but now people want to know if they can run their printer from a phone.

I checked my notes, and during my time at Tom’s Hardware, I have reviewed one hundred 3D printers, both resin and FDM. I’m well past that number if you also count several machines that we had to pass on due to unforeseen circumstances, or the handful of personal printers I acquired for fun.

Modding your 3D printer was common practice back then, especially if you had an Ender. For many, tricking out a $99 machine was the whole point of getting into the hobby. When I reviewed 2022’s new “luxury” Ender 3 S1 Pro, I had to explain that the exorbitant $479 price tag was because it included about $350 worth of mods.

Ironically, my “no mods needed” Ender 3 S1 Pro didn’t stay stock for long. These days, it’s running a BigTreeTech Klipper pad for speed and a 3D printed nozzle cam for close-up video. It’s still my favorite machine for running TPU because it’s slow, steady, and has an extruder that grabs filament like a pitbull.

The Ender 3 S1 Pro is a prime example of a pattern I see in 3D printer releases again and again. A new machine launches, looking like the pinnacle of perfection, but give it a year, and manufacturers will come up with something faster, smarter, bigger, or more colorful, and we pull out our wallets once again.

Looking back at these last 100 reviews, I’ve come up with a list of the best 3D printing mods that have become non-negotiable standards.

Auto Bed Leveling

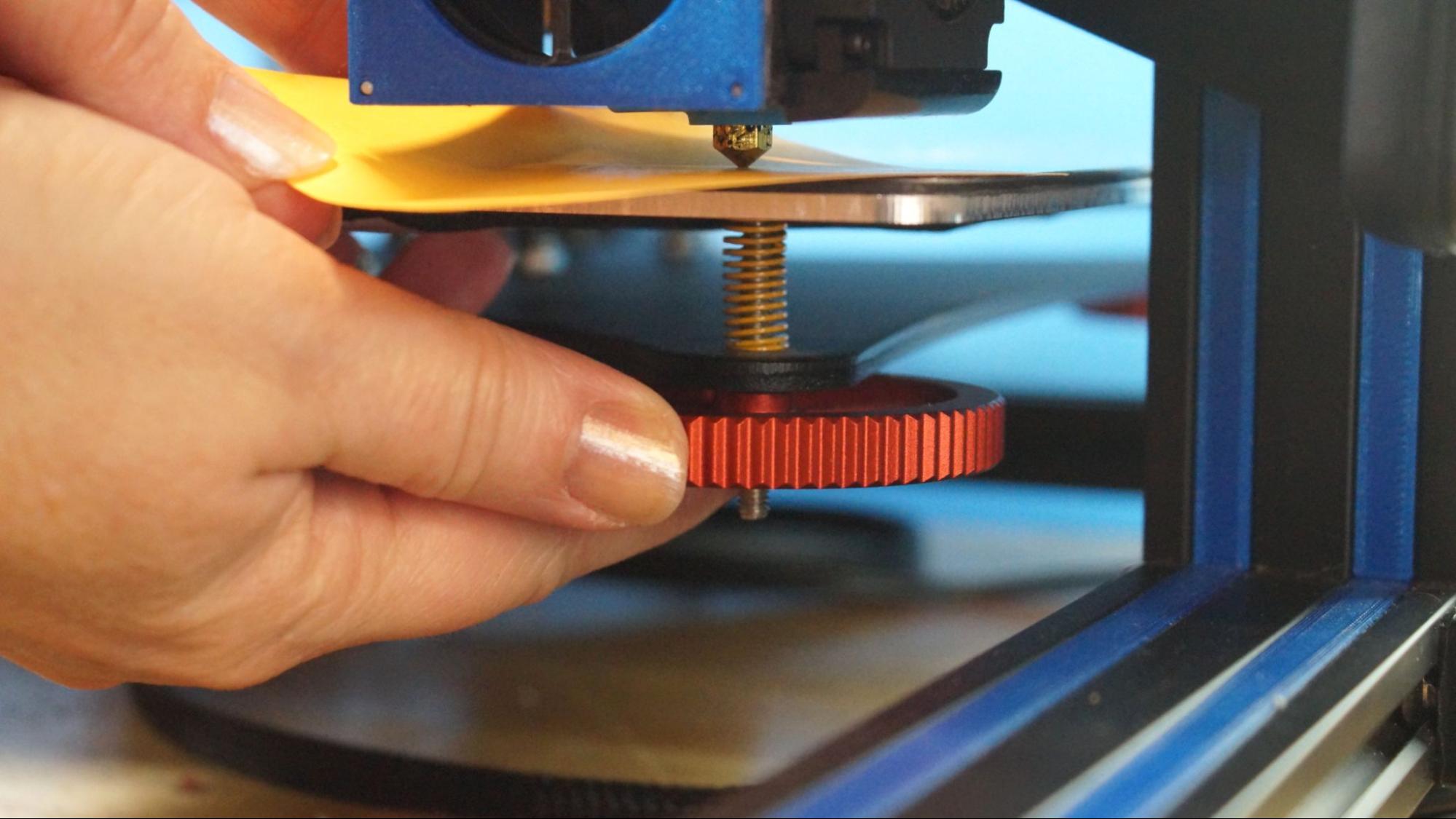

If I wanted to scare a group of makers around an evening bonfire, I would weave a tale of blood-curdling horror: 3D printers without auto bed leveling. Boo! If your first printer was a Bambu Lab, you’ve been spared the pain of manual bed leveling. Budget 3D printers used to have knobs under the bed to “tram” the surface flat in relation to the nozzle. Even early Prusa MK2s with their fancy, built-in PINDA probes might require a “live adjust Z” to perfect the print.

Bed leveling was a tedious process that required a slip of paper to literally feel the space between the nozzle and the bed and guesstimate if the gap was enough. Cheap printers often compounded the problem by shipping with warped beds that needed to be physically shimmed with layers of tape or tinfoil.

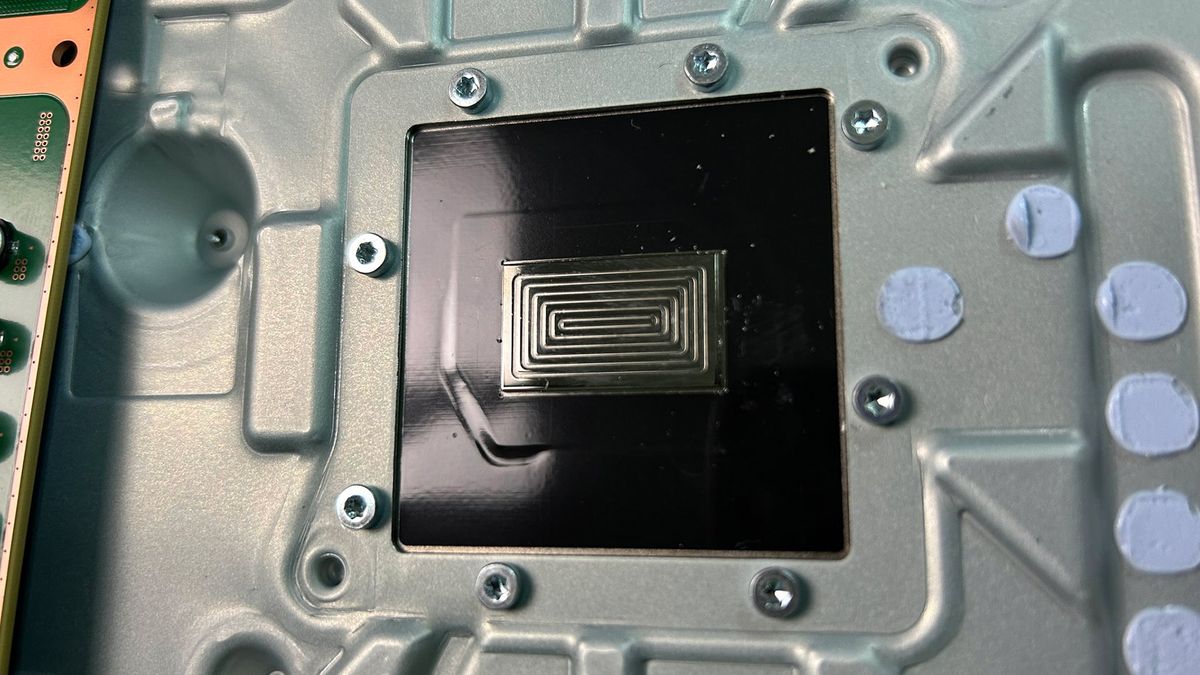

Now we have an assortment of probes, sensors, and lasers to analyze a printer’s surface and save an accurate bed mesh for future reference.

Grippy Removable Bed Surfaces

Getting prints to stick to the bed has always been a struggle for 3D printers. Early machines often had permanently fixed print surfaces, or if you were lucky, a stiff plate clipped in place. Go back a bit further, and printers didn’t even have heaters. Plates might be optimized for adhesion, but not removal.

Successfully printing on a glass bed without the use of glue stick, painter's tape, or hairspray was something to brag about. Removing that print, however, took time, a scraper, and sometimes a hammer.

Pioneered by Wham Bam Systems, flexible plates with a variety of coatings for every filament are now the norm. Today, I’d be shocked to find a 3D printer without some kind of miracle-coated flex plate. Since build plates are easily damaged and coating can wear off, there’s still a market for replacement plates. I wrote a whole list of my favorite aftermarket build plates here.

Speed

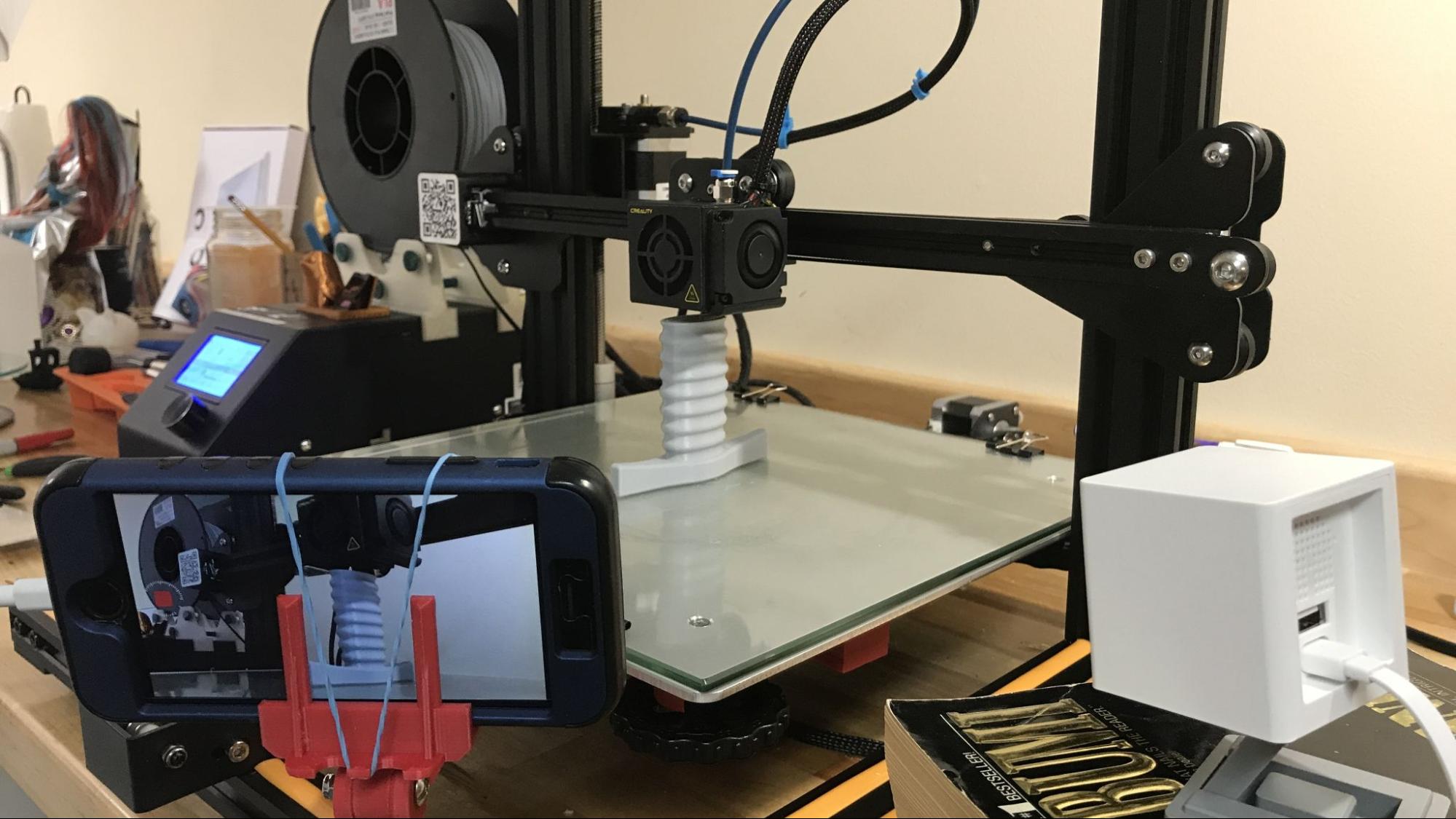

Bambu Lab made speedy 3D printers standard, but they were not the first to make 3D printers fast. We can thank Klipper for the original mod, which added extra processing power to the 8-bit boards on early 3D printers through an external Raspberry Pi. Klipper gave machines a performance boost by offloading motion planning to the Pi and adding input shaping and pressure advance for smoother prints at speed.

Programming a Pi was not for everyone, so for a while, we saw a rash of plug-and-play “Klipper Pads” to soup up your bed slinger. My old Ender 3 S1 Pro went from trudging along at 45mm/s to a zippy 150mm/s with this accessory.

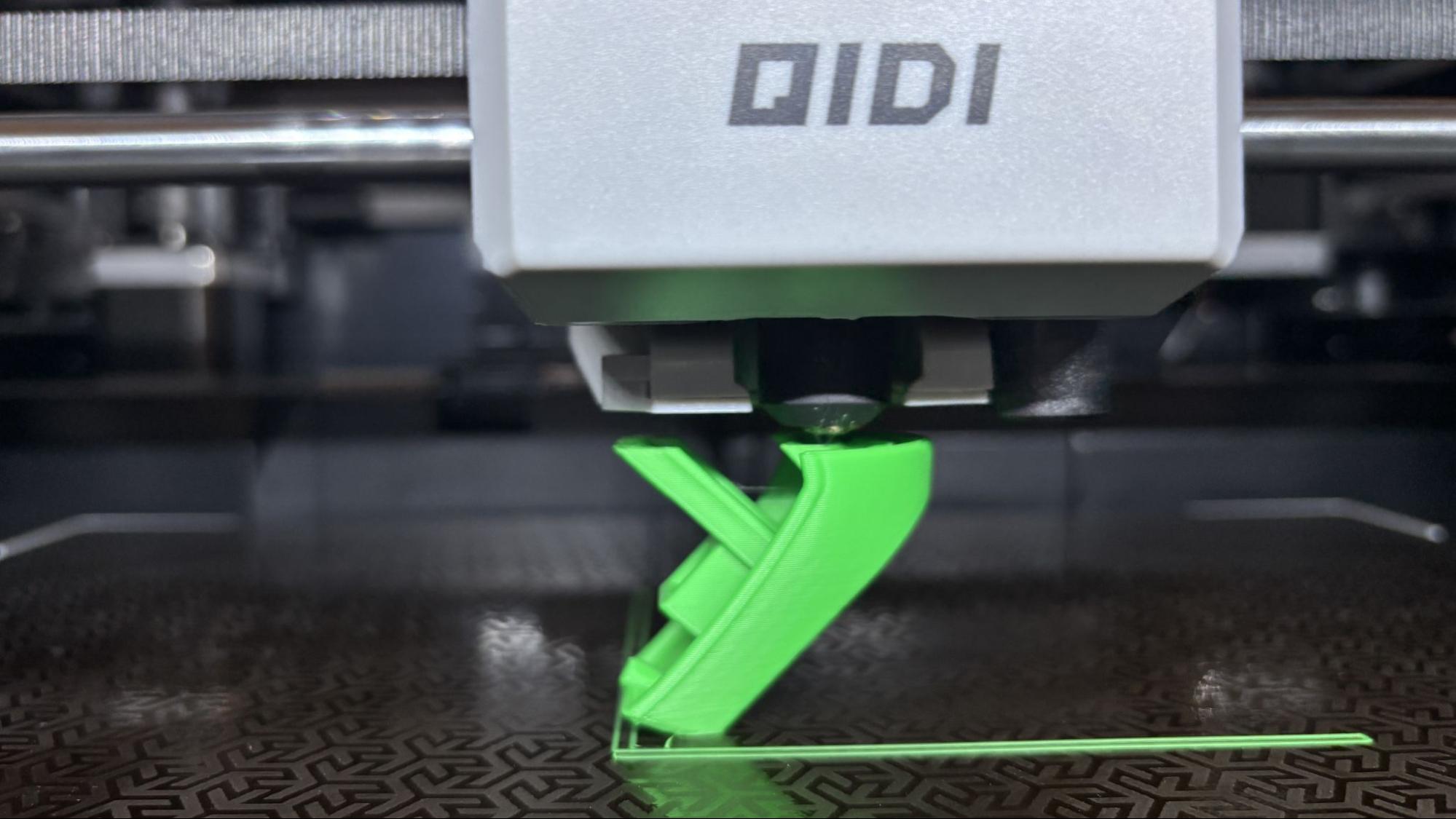

Now, manufacturers are putting bigger brains in their machines and using either Klipper or a homebrew version of input shaping. Combined with high flow hotends and massive cooling, we’re seeing print speeds from 300 to 500mm/s and beyond. The FLSun S1 can hit an impressive 500mm/s print speed, if you can handle the jet engine noise of its cooling system.

WiFi and Remote Access

Again, we can thank Bambu Lab for making a popular mod standard issue: remote access. New users would faint at the thought of transferring files from a computer to their printer via a tiny micro SD card. Before Wi-Fi, LAN, and the Cloud became common features, makers would need to use a Raspberry Pi with OctoPrint to send STL files to the machine over their home network. If you were already adding a Pi for Klipper, why not use OctoPrint, too?

Fun Fact: In the early days, Wi-Fi wasn’t added because people were too lazy to walk an SD card over to their printer. It was also done because many 3D printers used a cheap Micro SD Card, a tiny sliver of plastic that was easily lost on your desk, in your couch cushions, or in the huge gap between the card slot and the printer case. Gaining remote access to your 3D printer meant never looking for a lost micro SD card again.

Cameras

I am now infuriated when a new 3D printer doesn’t come with a camera for monitoring prints. The horror! After moving my office to a different part of the house, my machines remain a good 40 feet or more from my desk. Even the extremely budget-priced Elegoo Centauri Carbon came with a decent, if poorly lit, camera.

Combined with our new obsession with mobile apps, you can check your print progress from upstairs, the office, or even the grocery store.

Gone are the days of converting security cameras into printing babysitters, though Prusa Research will still let you use an old iPhone to monitor machines through Prusa Connect if you’re feeling old school.

Multi Color

3D printing in full, glorious color used to be a pipe dream. And an expensive one at that. In 2021, I dreamed of saving up for a Mosaic Palette, which could feed eight colors to my little Ender 3 Pro. It easily cost as much as three new Enders, and so was out of the question.

I went as far as trying out a crazy mod that used permanent markers to color prints. Needless to say, turning an Ender into a tool changer to draw on your prints was difficult and didn’t work well.

Pioneered by Prusa Research and made affordable by Bambu Lab, we now have multicolor systems for nearly every brand of manufacturer. I’m happy to report that printing in 4, 5, or 25 colors is now pretty easy, if not cheap. And with Snapmaker’s new tool changer on the horizon, the 3D printing world is turning very colorful indeed.

Click here if you want to see our current favorite picks for multicolor 3D printers, and taste that rainbow.

3 months ago

57

3 months ago

57

English (US) ·

English (US) ·