A recent paper from CHI 2025 postulated a new method to make multi-material 3D prints recyclable. Finding places that will recycle 3D printed plastic is extremely difficult as it is, but when you combine two or more materials in one print, it becomes impossible. This is because many 3D printing materials are incompatible with each other, and mixing them together would create a lumpy, unprintable mess.

The method devised by researchers from the University of Colorado Boulder incorporates water-soluble seams and joiners directly into the design itself, placing them between different materials. They propose using PVA, which is already in use as a water-soluble support material. These PVA buffers need to be woven into the model to maintain strength and integrity. Once the printed model is worn out, it can be dunked in water to dissolve the PVA, and the different materials can be sorted for recycling.

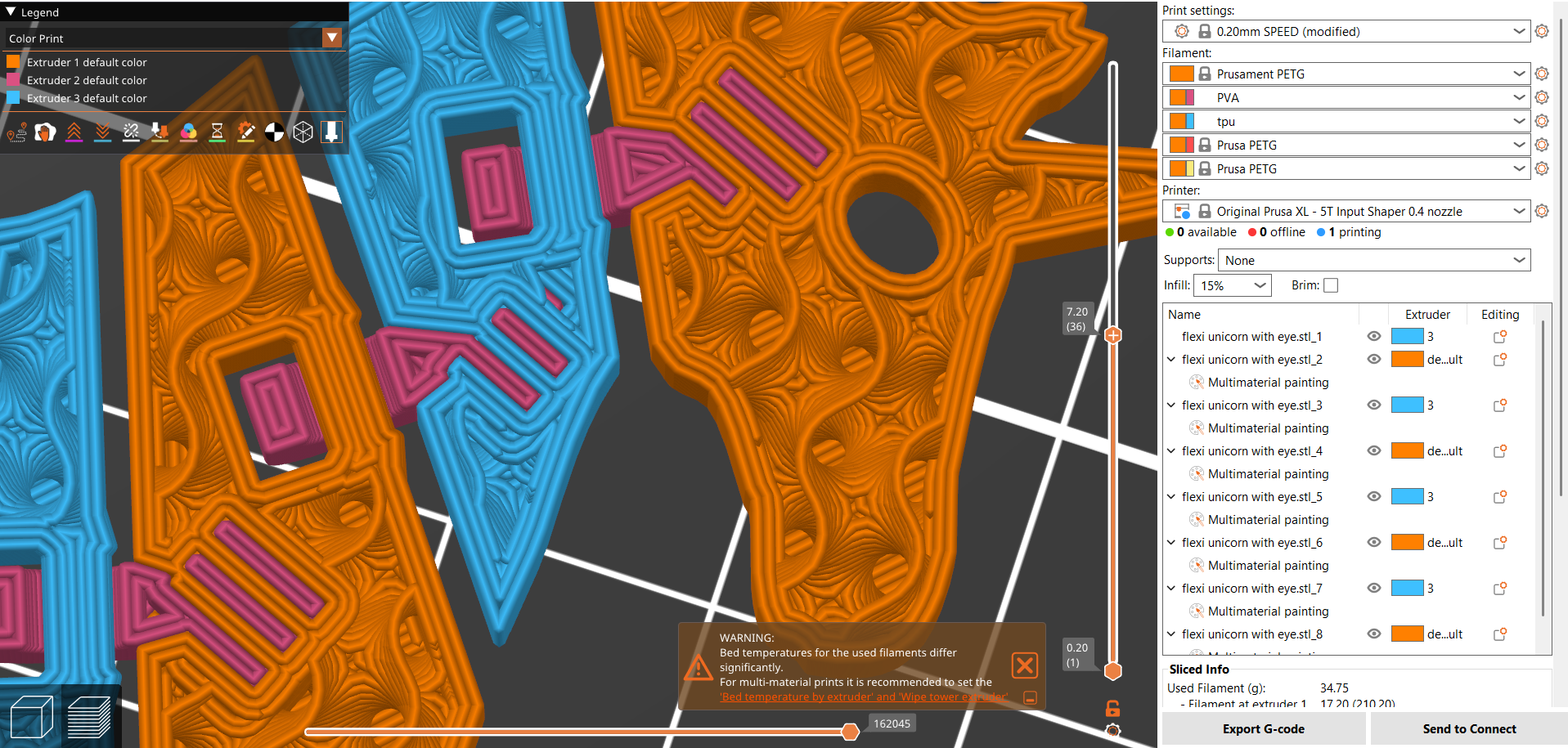

You can (crudely) test this method yourself with PrusaSlicer or Bambu Slicer by painting a model with different materials, then turning on Beam Interlocking. In the example below, water-soluble PVA is pink, while the other parts are PETG and TPU. Beam interlocking weaves materials together that normally won't bond.

The paper is really more of a think piece, as there are limited avenues for recycling 3D-printed plastic. Your average commercial recycling company won’t touch PLA and ABS with a ten-foot pole, because not only is it unlabeled, but even if it were, it couldn’t be recycled. Check the back or bottom of any commercially made item, and you’re bound to find a number inside three arrows forming a triangle. That number corresponds to the type of plastic it's made of, and therefore, how to recycle it. Soda bottles made of PET have a "1", while milk jugs made of Polypropylene would have a "5". And even if they trusted us to label our homemade plastics, all the common materials, such as PLA and ASA, fall under "7", or “other”.

Despite the organic, farm fresh origins of PLA, it won’t break down under normal conditions. If a 3D print is thrown in the trash, it will end up in the local landfill, where it will stay for a very, very long time. This conundrum has led many makers to get crafty with their scraps, while a handful of ingenious companies seek a solution. Loop3D, out of Boston, launched a Kickstarter to create a desktop filament recycler that would both shred waste plastic and remelt it into filament. Artme3D from Germany produced a DIY filament maker, though you need to find your own method to grind the material down. Personally, I send all my PLA and PETG scraps to Printerior, where they mix community waste with industrial PLA remnants to produce fresh Recycled PLA.

If you don’t live near a recycler and don’t want to crush up your own Benchies in a coffee grinder, you do have options. PHA is a bio-based filament tougher than PLA and designed to decompose when exposed to microbes when left outside in a compost bin or if left on the roadside as trash. Tom’s Hardware has a sample spool of Biodegradable PHA from Polar Filament under testing, though it could take several months before we see it break down.

A brand-new filament company, Timeplast, has also sent us samples of its intriguing “time programmable” material that can dissolve in simple water. The material is still in its development phase, but company representatives are convinced that the world’s oceans would be a lot happier if all packing materials were made out of their proprietary plastic. The recipe is a secret, but we know the copolymer is largely made of water, sugar, cellulose, and vinegar. When dissolved, it leaves behind only benign byproducts, according to the company. Our sample prints turned into soup in less than an hour, but other formulas are more durable.

6 months ago

57

6 months ago

57

English (US) ·

English (US) ·