Serving tech enthusiasts for over 25 years.

TechSpot means tech analysis and advice you can trust.

Forward-looking: Semiconductors are essential for today's electronics, providing computational capabilities and the ability to control electric signals. They are also highly complex and costly, so researchers have proposed a cheap, "semiconductor-free" way to achieve electronic democratization.

A team of scientists from MIT made a remarkable discovery while trying to make magnetic coils using extrusion printing. The process melts a filament and ejects the resulting material from a nozzle, printing a 3D shape layer-by-layer. Extrusion is a known 3D-printing method engineers can use to generate logic gates that can control electricity without any semiconductor components.

The researchers claim their method is suitable for printing resettable fuses, an essential element for active electronics. The team manufactured the devices with standard, affordable 3D printing machines and inexpensive, biodegradable polymer material doped with copper nanoparticles. They discovered that if a large amount of electric current passes through the material, the printed logic gates exhibit a spike in electrical resistance before returning to their original state after the current flow is interrupted.

In their study, MIT engineer Jorge Cañada and principal research scientist Luis Fernando Velásquez-García exploited this semiconductor-like capability to print switches. While they have no computational capabilities compared to silicon-based transistors, these polymer switches performed well in more mechanical functions, such as turning a motor on and off.

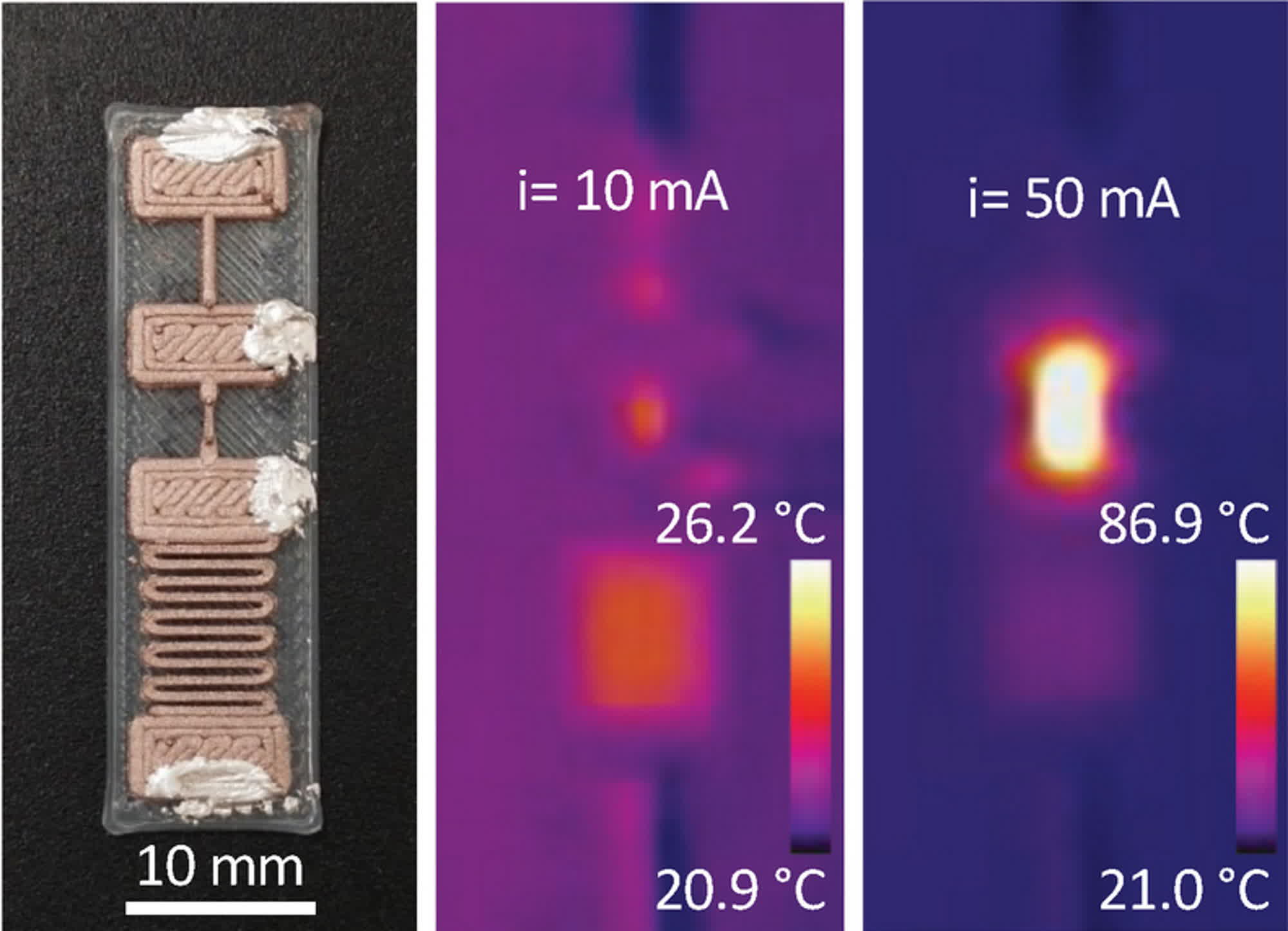

Figure 3. Example of the behavior of a 3D-printed conductive trace of varying cross-section when subject to high electric current. Optical image (left) of a 3D-printed circuit comprising several geometries in series and thermal images of the circuit when applying 10 mA (center) and 50 mA (right).

"This technology has real legs. While we cannot compete with silicon as a semiconductor, our idea is not to necessarily replace what is existing, but to push 3D printing technology into uncharted territory. In a nutshell, this is really about democratizing technology. This could allow anyone to create smart hardware far from traditional manufacturing centers," Velásquez-García told MIT News.

The printed logic gates were reliable even after thousands of switching cycles. Velásquez-García explained that manufacturers could use this method in cheap devices that don't need the "best" transistor-based chip on the market.

"At the end of the day, all you care about is whether your device can do the task," he said. "This technology is able to satisfy a constraint like that."

The MIT team is trying to depict the newly discovered 3D-printing method as a potential solution to the accessibility issue of semiconductor manufacturing. Active electronics components became highly sought during the COVID-19 pandemic, causing critical global implications and a significant price spike.

Easily printable logic gates with the proper material "recipe" could provide an alternative path to electronics manufacturing in laboratories, companies, and even in private homes, with no need to yield to economic speculation or manufacturing monopoly. However, the team is still working to develop an improved version of its technology. They ultimately want to advance the technique enough to print fully developed electronics with more complex circuits and better performance.

:quality(85):upscale()/2023/09/21/802/n/1922729/d9a11ce9650c8850437280.00070284_.jpg)

:quality(85):upscale()/2024/10/30/711/n/1922441/c62313206722590ade53c4.47456265_.jpg)

English (US) ·

English (US) ·